A major U.S. refinery was experiencing fouling in their naphtha hydrotreating preheat exchangers. The fouling resulted in early shutdowns hindering the refinery from making their catalyst change out dates. As a result, it became necessary for the refinery to minimize the fouling to extend their run length and meet their shutdown schedule.

Based on the feed quality and the severity of the fouling present, a comprehensive antifoulant treatment program was designed to help inhibit polymerization and disperse existing particles by preventing agglomeration and minimizing growth. This program was designed to provide the most effective treatment program specific for the customer’s unit.

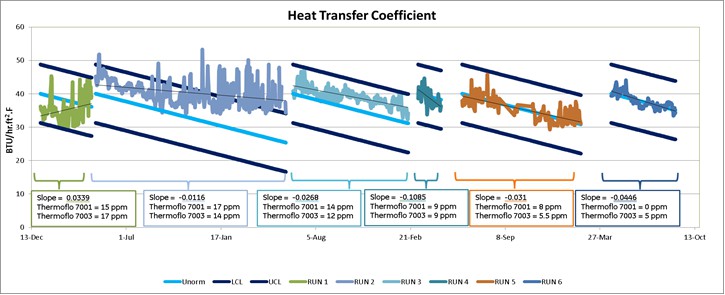

As a way of developing a base case model, Veolia utilized HXCoolPro*, a rigorous monitoring program that includes a two-phase heat transfer calculation. This allowed Veolia to determine the severity of the fouling present. The MRA/SPC technique was then used to generate a mathematical model using a baseline period and the key operational parameters that impact the Key Performance Indicator (KPI) – in this case, the heat transfer coefficient. The generated model provided the means for data normalization to a standard set of operating conditions, thus allowing Veolia to isolate the impact of antifoulant injection and determine the proper fouling trend.

Result

Figure 1 above shows the normalized trend of the heat transfer coefficient. Veolia’s Thermoflo* antifoulant treatment program was utilized in this application. In this graph, Run 6 was the base case because it was representative of an untreated system. As you can see, Runs 1-3 provided the best reduction in fouling with Run 3 having the lowest % reduction in fouling at about 40%. Runs 4 and 5, which were treated at very low dosages for this particular system, provided the worst performance with Run 4 being worse than even the base case. This is a clear indication of what can happen when the applied treatment goes below the minimum threshold, or below what has been recommended. This is an important clarification since antifoulants are unlike other treatment programs, since the applied dosage has to stay above a minimum threshold in order for it to be effective. When the refinery applied the comprehensive treatment program to the unit as recommended by Veolia, the exchanger fouling was no longer the limiting factor or the cause of shutdown for the unit.