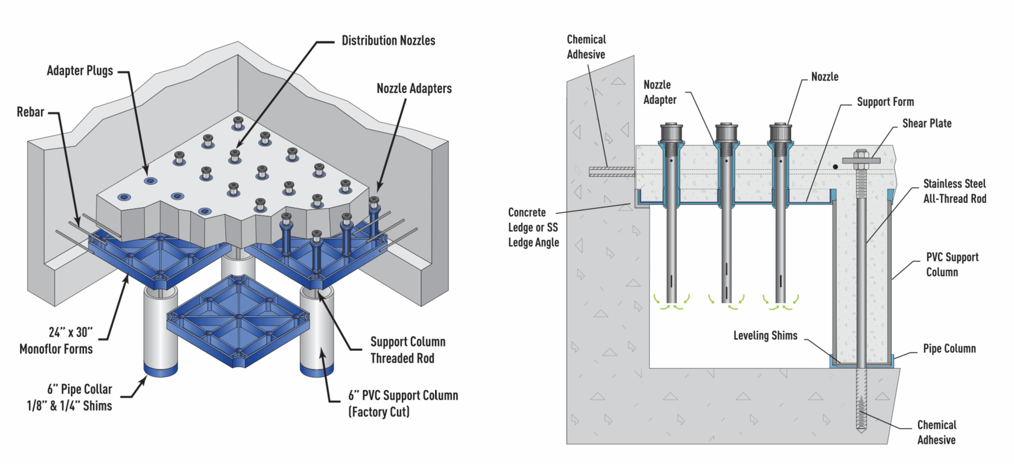

MNF underdrain

Pour-in-place concrete floor for filters

Pour-in-place concrete floor for filters

The MNF high-density concrete underdrain system is a single, poured-in-place concrete floor supported by polystyrene forms, incorporating air/water backwash nozzles. The system can be incorporated in most filtration applications including single media or multimedia for potable water treatment, advanced wastewater treatment, and various industrial filtration systems. MNF underdrains are ideal for many retrofit applications since few restrictions exist regarding filter size or orientation.