Challenge

Veolia’s NF beverage system installed at Coca-Cola HBC Poland’s facility in Radzymin.

Coca-Cola HBC Poland’s largest bottling production facility is located in the City of Radzymin. Being also the manufacturing centre for the Coca-Cola Hellenic Group, the plant features six production lines that yield all of Coca-Cola’s beverage products, including soft drinks, juices, and energy drinks. Products produced at the facility are shipped to many European countries.

The plant, located in a marshy area, uses pre-treated well water as its feedwater. In 2008, they switched from a reverse osmosis (RO) system to multi-media filtration (MMF) and ion exchange (IX) to lessen water consumption.

After a few years of operation, the Radzymin facility wanted to explore new options to increase the removal ratio of total organic carbon (TOC) from the feedwater in order to get the outmost quality and stability of feedwater for their products.

Solution

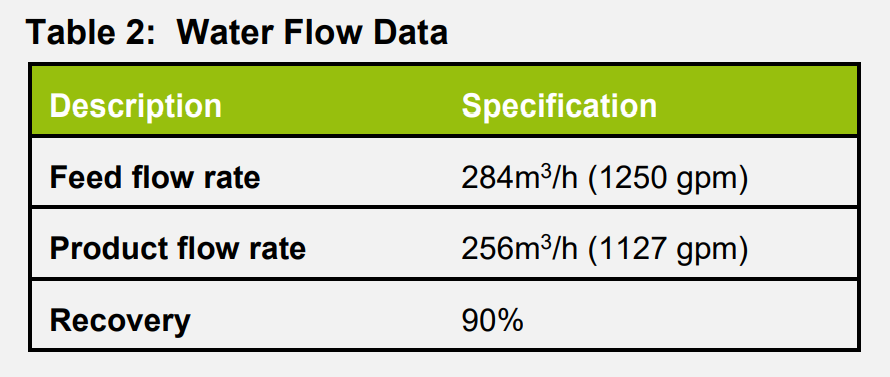

To optimize feedwater quality, Veolia recommended the use of nanofiltration membranes. Veolia’s solution entailed a two-line 256m3/h (1127 gpm) fully automated Nanofiltration (NF) beverage system to treat the well water after initial pre-treatment and pH adjustment. The product water from the BEV NF system, after filtration by activated carbon, is used directly in aseptic lines for production of final products.

Initially the project considered using an RO system as pre-treatment to the existing IX treatment scheme to remove the TOC. Veolia recognized that based on the water chemistry and nature of the organics, a true NF system would provide better performance and require less cleaning. The NF system was supplied with two chemical dosing stations and clean-in-place (CIP) capabilities to ensure optimal reliability and ease-of-use.

Veolia’s European-built BEV NF solution was designed with metric measurements and manufactured according to strict European Union standards.

Veolia’s European-built BEV NF solution was designed with metric measurements and manufactured according to strict European Union standards. Veolia met a tight deadline to ensure complete installation, commissioning, and performance testing prior to peak production season.

Result

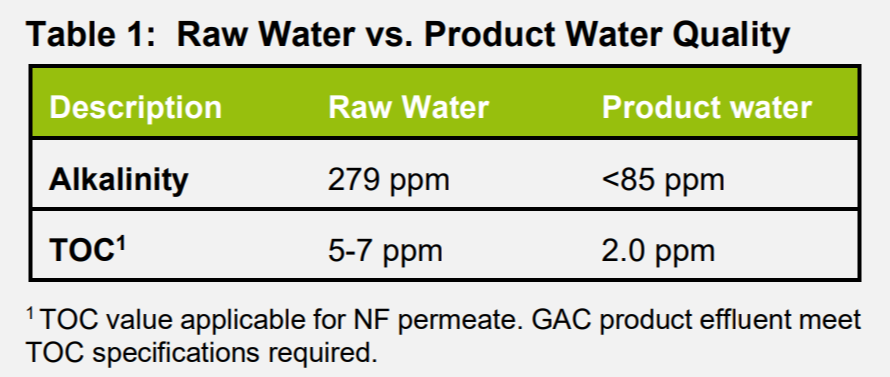

The Veolia BEV NF system designed for Coca-Cola Radzymin provides high quality water with low TOC and low alkalinity. The ingredient water supplied by the BEV system supports the production of about 772,000 x 0.33 litre cans per hour.

The BEV NF System was designed to maximize the water efficiency, with 90% of the feedwater being further treated as ingredient water thanks to an ICR (Integrated Concentrate Recovery) system. In addition, the BEV NF system eliminates the need for frequent multi-media filter (MMF) backwashing and IX resin regeneration by employing CIP, a much less water-intensive and time-consuming way to clean equipment, allowing the plant to save on raw water intake.

The Veolia Nanofiltration Beverage (NF BEV) System is designed to operate in a microbiological safe environment, allowing continuous chlorination and elimination of dead-zones, thanks to a special NF element design and plant components. Tables 1 and 2 show the water quality and flow data.