- Gaseous fuels

- Solid fuels

- Liquid fuels

- Water

- Sludge

- Fuel flow

- Corrosion of tanks and bacterial growth

- Specific equipment problems

- Safety

The heart of any boiler is its fuel system. Fuel handling and storage problems can limit the efficiency of the entire boiler.

There are three forms of boiler fuel: liquid, solid, and gas. Methods of handling and storage vary according to the type of fuel used.

Clean and relatively moisture-free gaseous fuels present little difficulty in handling. Natural gas is a prime example of clean fuel and is the one most commonly used in boiler systems.

Dirty gas, such as refinery gas, blast furnace gas, carbon monoxide gas, and other waste gases from processes, can cause significant handling problems. Special measures must be taken to prevent escape to the surrounding atmosphere, fire, fuel line deposition, moisture, and incomplete combustion. The severity of the problem depends on the specific contaminants in the gas. Methods of handling are selected according to the nature of the specific gas and local regulations.

Wet scrubbers, electrostatic precipitators, chemical dispersants, and suitable pipe and tank lagging may be used to eliminate problems. Wet scrubbers and electrostatic precipitators remove contaminants mechanically. Chemical dispersants have been used in conjunction with wet scrubbers and electrostatic precipitators to handle troublesome contaminants. Because leakage is one of the major concerns in handling gases, some method of leak detection is essential. The selected method may be as simple as detector-type sprays or as sophisticated as combustible detectors with alarms, which may be connected to automatic fire control systems.

Solid fuels (including coal, wood, and solid waste) present some of the same handling difficulties. Problems occur unless a free-flowing, continuous supply of fuel that is properly sized for the specific type of combustion equipment is provided. The problems include sizing, shredding or pulverizing, consistency of moisture content, freezing or lumping, dusting, fires in storage due to spontaneous combustion, and fires in the feed or ash handling systems.

Most problems can be minimized or eliminated through proper selection of fuel handling equipment. Specific types of equipment for handling, storage, and preparation depend on the characteristics of the solid fuel used.

Because the proper equipment is not always available, fuel additives or aids have been used in the attempt to minimize problems. These additives include grinding aids, moisture improvers, dusting aids, freezing inhibitors, and catalysts to minimize combustibles in ash and fly ash handling systems.

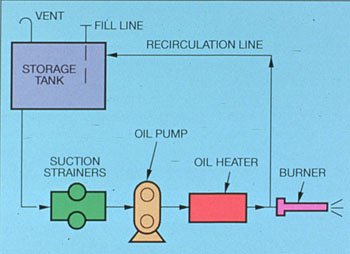

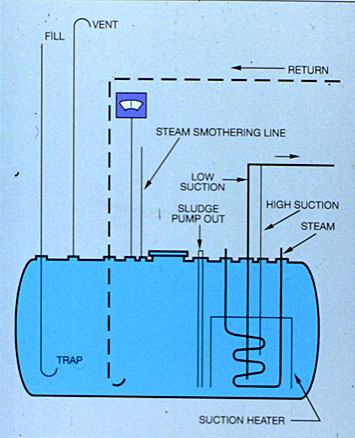

Liquid fuels include waste oils, light oils, heavy oils, and other combustible liquids. Because of the problems of liquid residue disposal, an increasing variety of combustible liquids is being considered and tested. Figures 20-1 and 20-2 illustrate key components found in a typical liquid fuel handling system and fuel oil storage system, respectively.

Problems encountered in the handling, storage, and preparation of liquid fuels include water contamination, sludge formation, resistance to flow, biological growths, instability, and corrosive-ness. Generally, these conditions are manifested as excessive strainer plugging, poor flow, increased loading on the fuel pump, heater deposits, fuel line deposits, loss of storage space, burner tip deposits, burner fouling, leakage due to storage tank corrosion, poor atomization, and other combustion problems. Table 20-1 summarizes the nature and cause of problems associated with key liquid fuel handling system components; some of these conditions are illustrated in Figures 20-3 - 20-4 and 20-5 - 20-6.

Table 20-1. Preboiler problems and their causes.

| Location | Problem | Cause |

| Storage Tank | sludge reduces available volume of fuel oil storage | sludge may have resulted from more than 7 days' storage or from using several oil sources |

| Suction Strainers | frequent cleaning necessary | sludge is being carried over from storage tank |

| loss of oil pump suction | sludge is being carried over from storage tank | |

| Oil heater |

plugging loss of oil temperature varying oil temperature |

sludge is being carried over from storage tank; oil has become polymerized |

| Burner |

poor atomization distorted flame patterns reduced maximum laod frequent cleaning necessary difficulty cleaning burner oil flow discontinuity |

high oil viscosity; sludge is being carried over from storage tank; high burner temperature; water in oil |

Water can become emulsified in oil during processing and can also be introduced into oil during handling by condensation, contamination, or leakage. The presence of water can lead to many problems:

water that separates from oil is generally acidic and can readily corrode storage tanks, particularly at the oil/water interface

separated water occupies useful storage space

water at the burner can cause oil flow discontinuity

if it enters the firing system in sufficient quantity, water may cause thermal shock, leading to refractory damage

Most water can be eliminated by means of careful shipping and handling procedures. Proper design and maintenance of equipment can also minimize water leaks, such as those resulting from steam heater or tank leaks. To minimize condensation, proper lagging and heating of the tank are necessary.

Properly selected additives can be used to emulsify small amounts of water (up to approx-imately 1%) economically. Large quantities of water should be removed physically from the tank by draining or pumping. When large amounts of water are detected, the source should be identified and corrected.

Water in storage tanks can be detected by means of a Bacon Bomb. This device is lowered into a tank and opened to allow sampling at any point beneath the surface. The sample can then be evaluated by testing for bottom sediment and water (BS&W). Testing for water can be as simple as waiting for the sample to settle in a graduate.

Sludge is composed of settled heavy agglomerates combined with suspended matter from an oil or liquid fuel. Sludge formation increases when fuel oils of different crudes or liquid fuels of different sources are mixed. When fuel oils are heated in a tank to ensure good flow, the likelihood of sludge formation is increased. If the heat is high enough to break the water in oil emulsion, the heavier agglomerates may settle. Sludge formation in the tanks reduces storage space for usable fuel and removes part of the high energy containing components of the fuel. Frequent strainer cleaning is required to prevent high pressure drops and ensure good flow. Sludge formation can also cause heater burner tip fouling. Sludge can be detected in a storage tank by Bacon Bomb sampling of the tank.

In order to mix settled sludge with new fuel, it helps to fill the storage tank from the bottom. A tank with effective lagging (outer insulation) is less susceptible to sludge buildup. Long-term storage (over 7 days) should be avoided and some method of recirculation employed to keep the heavy agglomerates mixed. Where mechanical methods are not completely effective and/or some degree of help is desired, additives are effective in dispersing sludge, even at low use rates. The additives help clean fouled storage tanks and heater and burner assemblies, on-line or off-line.

Many advantages result when fuel sludge is minimized:

- Increased energy content in the fuel increases efficiency.

- Clean tanks afford maximum utilization of storage space.

- Clean feed lines, heaters, and burners are essential to good flow and good combustion.

- Proper fuel conditioning produces good flame patterns, reducing the chances of flame impingement.

Proper fuel flow allows the boiler to operate at maximum capacity and helps control the formation of burner deposits. It also allows operation at minimum excess air, which helps control slagging and high-temperature corrosion.

The resistance to flow of a liquid fuel is a function of viscosity and pour point. A higher temperature lowers viscosity and increases the ability of the fuel to flow. It is important to maintain the correct temperature range in a storage tank to ensure good fuel flow and prevent vaporization of the light oil fraction.

One method used to control pour point involves blending of oils with differing pour points. Care must be taken because the pour point of a mixture can be higher than that of either of the two components. As a result, solidification and crystallization can occur in the fuel, which can completely plug a fuel pump. Such plugging is almost impossible to remove through normal cleaning methods. High temperature and constant motion are advisable when high pour point fuels are used.

Viscosity also affects atomization of the oil by the burner. Proper atomization requires lower fuel viscosities than those needed for good fuel flow. This lower viscosity is obtained by heating. Only preliminary heating may take place while the oil is in its storage tanks, to prevent vaporization of the lighter oil fractions. Following preheating, the oil flows to an in-line heater where it is heated to a temperature suitable for good atomization.

CORROSION OF TANKS AND BACTERIAL GROWTH

Water that separates from fuel oils is almost always acidic. Although most hydrocarbons are protective by nature, corrosion can still be found at the water/oil interface. In practice, an alkaline material or amine-type additive is added to protect metal surfaces.

Because heavier fuel oils do not provide life-sustaining nutrients, they rarely experience bacterial growths. In lighter fuel oils, such as diesel fuels, bacteriological growth has been found at the water/oil interface. In order to prevent this occurrence, it is necessary to use water-free fuel oils or to prevent separation of water from the fuel. When bacteriological growths are not prevented, they can be controlled by antimicrobials.

Corrosion test specimens can be installed at the water/oil interface to monitor corrosion, eliminating the need for periodic equipment inspections. Bacterial growth monitoring requires sampling at the water/oil interface and testing for bacteria count.

Fuel strainers protect the fuel system from problems with heavy agglomerates and suspended matter. The strainers are relatively coarse, because fine straining can retard fuel flow and increase required cleaning frequency.

Fuel oil pump selection should be based on the anticipated suspended solids in the fuel, along with the type of additive to be used for fireside protection. For example, a constant differential pump operates at a constant rate, and varying amounts of unused oil are recirculated as loads vary. This recirculation, together with certain additives, may increase the amount of suspended solids in the fuel, thereby increasing the clearance tolerances needed. Naturally, the tolerances can be much closer for very light, clean oils than for heavier fuels or fuels carrying more suspended solids.

Burner nozzles are affected by suspended matter and are subject to wear. The effect of wear on the nozzles can be determined by observation of the flame pattern or by means of "go or no-go" gauges.

In-line heaters and burner tips develop clogging problems due to high temperatures, which cause some solidifying of heavier hydrocarbons. Problems with the in-line heater are revealed by pressure drop across the heaters, a decrease in fuel oil temperature, or an increase in the steam pressure required to maintain the same oil temperature. Burner tip deposits are indicated by distorted flame patterns or inability to achieve maximum load due to restricted flow.

Proper fuel handling must be maintained to ensure optimal conditions and thereby minimize these problems. In addition, periodic cleaning is often necessary. When the required frequency of cleaning is excessive, an additive may be used to help keep the heavy agglomerates dispersed and flowing easily.

Liquid fuels require care in handling to maximize safety. Potential problems include contamination from spills or leaks and escape of combustible vapors. Tank areas should be diked to contain any spills. To guard against fire, special tank construction is necessary and combustible vapor monitors should be used. Combustible monitors may be integrated into fire control systems.

Figure 20-1. Typical preburner system flow diagram.

Figure 20-2. Typical arrangement of fuel oil storage tank.

Figure 20-3 and Figure 20-4.

|

Figure 20-3. Fuel strainer with deposits |

Figure 20-3. Fuel strainer with deposits |

Figure 20-5 and 20-6. Clean burner nozzle and burner nozzle affected by suspended matter.

Figure 20-5. Clean burner nozzle. |

Figure 20-6. Burner nozzle affected by suspended matter. |