Electrodialysis (ED)

For value-added demineralization of process streams

For value-added demineralization of process streams

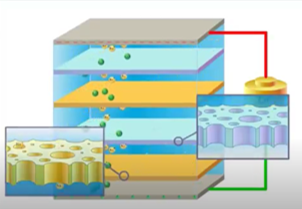

Electrodialysis is an electrochemical separation process that uses DC power to move ions through selective ion exchange membranes in order to remove salt from a feed stream into a concentrate stream, leaving a product behind with increased value.

This technology is used in markets and applications such as whey demineralization in dairy plants, sugar demineralization, glycerine and amine desalting, and juice deacidification.