Z.Plex* Depth Cartridge Filters

Highest capacity cartridges

Highest capacity cartridges

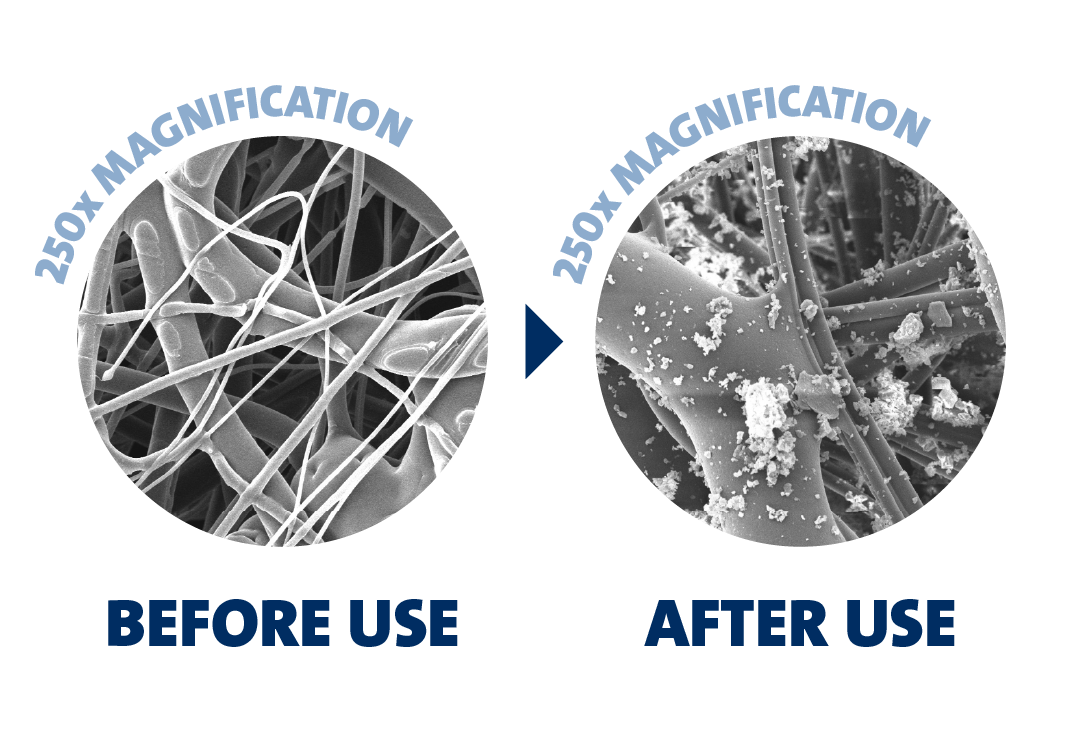

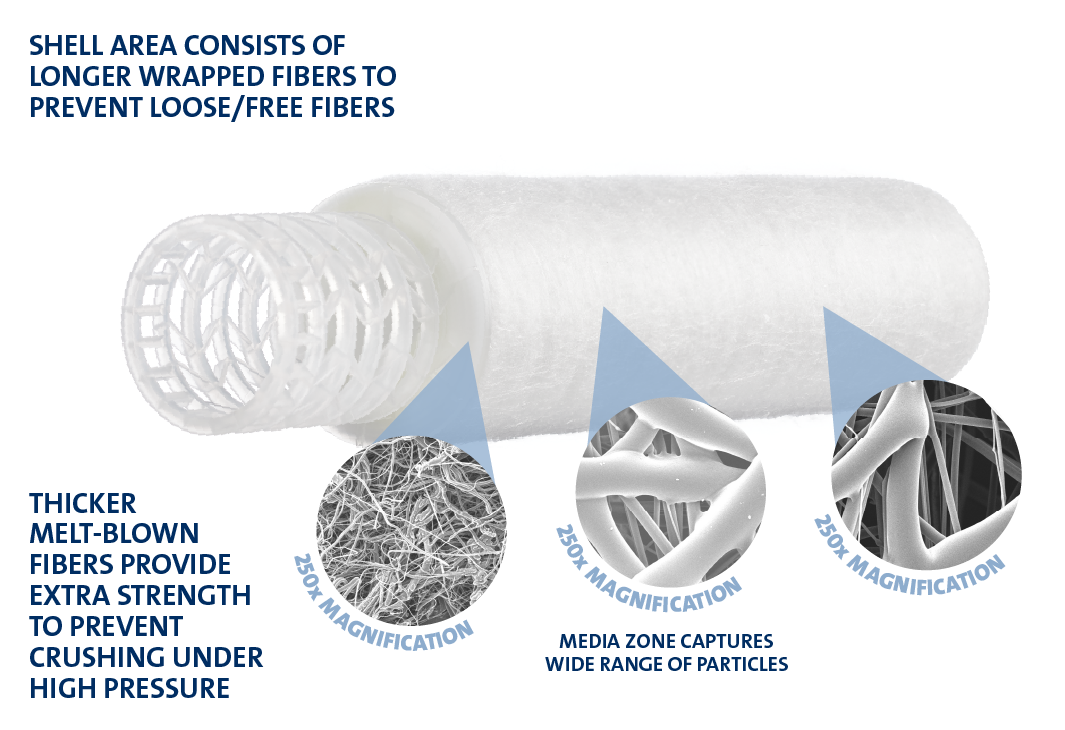

Z.Plex depth cartridge filters are manufactured using patented Z.Plex filter technology. Z.Plex’s proprietary graded density filter matrix provides exceptional performance with up to twice the life of conventional depth filters. The filters in the Z.Plex family have up to 50% lower pressure drop and up to 100% greater dirt-holding capacity. The melt-bonded exterior and core ensure no media migration, providing a lower total cost of filtration.