A brewer in the United States relied on outsourced manufacturing to produce a new beverage. As the beverage grew in popularity, they needed to build their own production facility.

The greenfield project required ingredient-water to be available quickly. Because of past partnering success with Veolia, they relied on our expertise for both design and installation of the ingredient-water system.

The customer needed a plant with 1500 GPM capacity and low total dissolved solids (TDS) product requirements. The local water source was especially high in dissolved minerals, so special considerations were required to ensure the membrane system would not be prone to scaling, leading to excessive cleaning costs.

Due to the water stressed region where the production facility was constructed, the brewer was also concerned about discharged effluent, associated fees and environmental impact. They wanted to maximize system recovery and reduce waste volumes.

Working with Veolia for both the design and installation provided a unique opportunity for innovative solutions in this greenfield plant:

- Traditionally designed reverse osmosis (RO) systems operate at a constant flow rate. This system included primary ROs that were single stage feed-and-bleed and allowed the customer to ramp the flow rate up and down. This provided the customer with increased flexibility in meeting plant demand and reduced machine downtime at lower flow demand.

- The design consisted of three primary ROs. The combined concentrate streams were fed into a single recovery RO. This direct feed, without a break tank, helped the customer limit the footprint of the plant and shortened the delivery calendar.

- The separate recovery RO system allowed for a higher system recovery and included a unique automated cleaning process. This minimized the risk of scaling membranes for the entire plant, increasing productivity and reliability while reducing cleaning costs. This automated cleaning process lengthens the time between full “clean-in-place” (CIP) and minimizes plant downtime.

- Veolia also installed a unique valve matrix which allowed the customer to more thoroughly CIP the interconnecting piping.

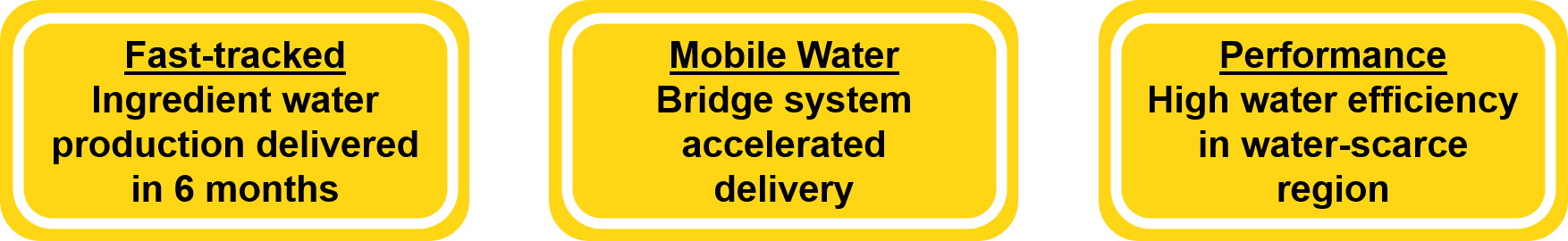

The required schedule was tight and was challenged by many supply chain demands during the global COVID-19 pandemic. To meet the needed schedule, Veolia provided:

- Short term ingredient-water production through a mobile water system. This bridge system allowed for on-time ingredient water production, prior to full installation being completed.

- Short term Operation and Maintenance (O&M) services to operate the system prior to customer taking over operation.

- Enlighten* services to train the customer’s team and ensure a smooth transition as well as a multi-year service contract to provide continued support for ongoing system performance.

Result

Through the use of the temporary mobile water bridge solution, the customer’s ingredient water production needs were met, and the new brewing facility was able to start production within the required timeline.

The ingredient water system was customized to consider the requirements for treating influent water with a high salt content and incorporated unique functions to maximize recovery rate and minimize waste volumes.

Furthermore, Veolia provided an O&M service package to ensure the system was fully commissioned, delivered on all KPIs and trained the customer’s team to be ready for operation.

If you would lo learn more about how Veolia can provide solutions for your ingredient water needs, please visit our website.