Semi-arid Redlands, some 50 miles (80 km) east of Los Angeles, receives only about 15 inches (38 cm) of rainfall annually and relies partly on wells to supply water to the area’s 75,000 residents during peak summer usage. Ongoing development and anticipated periods of below-average rainfall continue to stretch the area’s water supply.

Conserving the precious groundwater supply was the main driver for Redlands to go before the California Energy Commission (CEC) in 2000 and advocate for recycled water to supply the cooling towers at the 1,056-megawatt (MW) Mountainview Power Company (MPC) power plant. The MPC’s plan to use a series of large wells for cooling water would place a tremendous strain on the region’s future groundwater supply. Redlands proposed to the CEC an environmental and economical way to treat the City’s wastewater and produce the necessary high-quality process cooling water.

In 2000, the City of Redlands searched for the best available technology to implement its concept and upgrade treatment at its existing 9.5 MGD (35,960 m3/day) secondary wastewater treatment plant (WWTP) with a technology that could make 6 MGD (22,710 m3/day) of high-quality recycled water intended for water reuse (California’s Title 22). Working with Carollo Engineers’ San Bernardino office and CH2M Hill, the City examined multiple alternatives.

The city selected Membrane Bioreactor (MBR) technology for the plant upgrade. Membrane system proposals from three manufacturers were evaluated and the city selected Veolia’s ZeeWeed* ultrafiltration membranes for its superior quality effluent, its robust performance and the overall value that the system provided for both the City of Redlands and for MPC.

The 14,000-foot (4,270-meter) distribution line that delivers cooling water to the power plant was equipped with many turnouts to also serve other potential customers along the way. Since start-up, the recycle water system has expanded and now supplies a number of additional customers including irrigation users within the City, dust control at the neighboring landfill and plant water in local businesses.

As planned, the Redlands WWTP MBR system, commissioned in 2004, treated over 60% of the full plant wastewater flow of 9.5 MGD (35,960 m3/day) to meet water reuse quality requirements. The remainder continued to be treated by the pre-existing conventional system. The design included a future system upgrade to treat the full 9.5 MGD plant flow with MBR technology through the addition of 3 more membrane trains.

At that time, membranes in an MBR environment were still a relatively new concept and expected to have a life expectancy of 7-8 years. Far exceeding initial expectations and after over 15 years, the plant installed their first set of replacement membranes in 2020. With new developments having been achieved in MBR membrane technology, Redlands evaluated multiple membrane supplier proposals again and determined the best option was to upgrade to the latest Veolia ZeeWeed ZW500D MBR membranes with LEAPmbr* aeration technology.

Once the 6 MGD MBR system was upgraded with the new ZW500D membranes, their increased filtration surface area and improved permeability was able to continue treating the 6 MGD MBR flow and also provide enough additional capacity within the original 6 membrane trains that Redlands will now be able to eventually achieve the full flow requirement of 9.5 MGD within the original membrane tanks. This will save the City the cost of adding the 3 supplemental trains, as was originally planned.

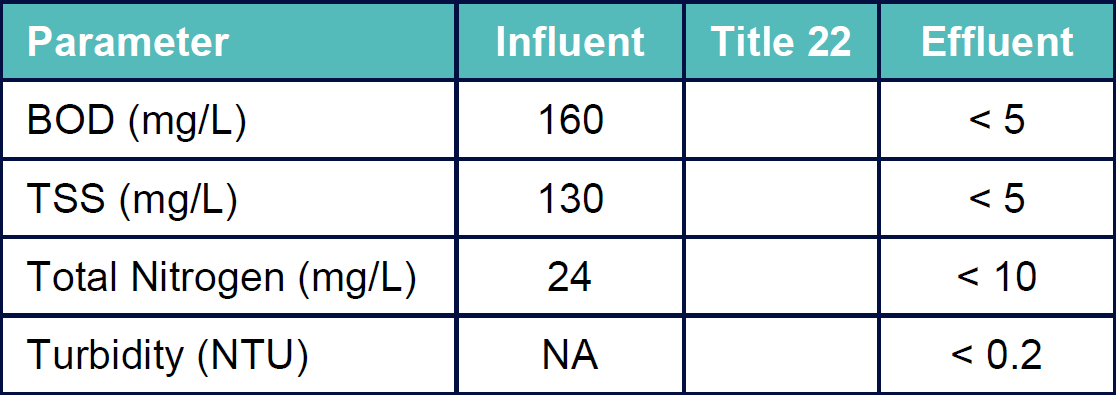

Table 1: Typical Redlands WWTP treated water results

Result

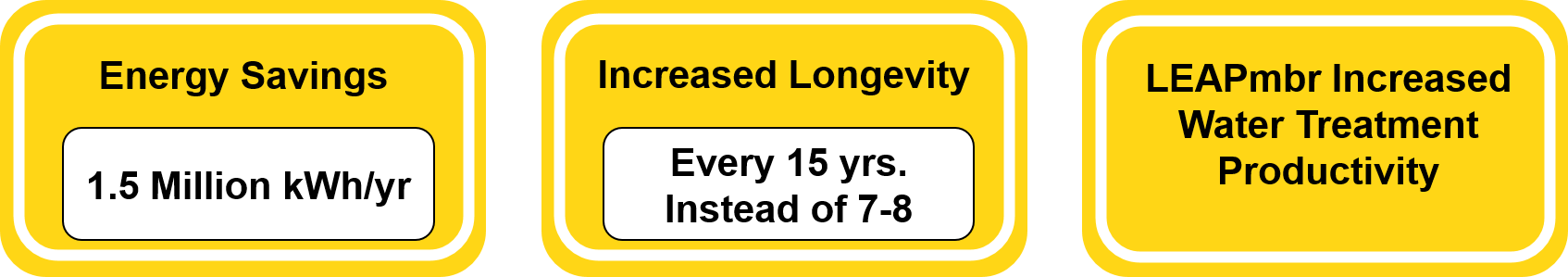

The original plant commissioning created an efficient and effective water quality and recycling program that met the environmental and economic needs of the City of Redlands and the MPC power plant. The longevity of the original MBR membranes provided ~100% costs savings to the city by only being replaced once in 15 years, compared to the initial expectation of every 7-8 years.

The upgraded LEAPmbr membranes allow for increased water treatment productivity in the membrane basins by ~60%, that will eventually allow Redlands to treat the full 9.5 MGD design capacity of the plant without additional space or capital expenses for new membrane trains.

Energy savings are achieved through increased equipment efficiency and improved blower controls, along with some equipment reduction providing additional savings in operations and maintenance. The new LEAPmbr membrane system requires less membrane air scour aeration, reducing its energy consumption compared to the original installation. The heart of the energy-efficient MBR system is the controls, which are integrated with the new blowers and can modulate air flow based upon actual demand rather than the indiscriminate cleanings that were previously applied. This new control methodology allows the system to operate at lower turndown flow rates for the scouring blowers by constantly monitoring blower operations, resulting in unprecedented level of energy efficiency.

The 6 MGD MBR replacement project resulted in a total energy savings of more than 1.5 million kWh/yr, equivalent to the elimination of 600 tons of CO2. This saved the City an estimated $152,000 per year in energy, plus $290,000 in incentives from the WISE program administered by Southern California Edison.

Figure 1: The 6 MBR trains at City of Redlands WWTP