Challenge

A hydrogen plant in Alberta, Canada, was at risk of losing processing capacity due to suspected calcium carbonate scaling occurring in the heat exchangers of the hydrogen unit’s reciprocating compressor. This scaling was reducing cooling water flow to the hydrogen compressor units, leading to a loss in capacity.

The hydrogen compressor units raise pressure of plant product hydrogen, which is required to supply the naphtha and gas oil hydrotreaters (nitrogen and sulfur removal process). With limited hydrogen supply, these processes could not operate at peak levels, impacting overall site production. The customer was considering a compressor outage to clean the exchangers and restore normal production levels, but this would represent a significant cost as well as complex planning

Solution

The process technical engineer turned to Veolia to help analyze and confirm the cause of the reduced efficiency of the exchangers, and to recommend a solution.

Veolia reviewed the hydrogen plant system operating conditions, cooling water temperature and chemistry. From these findings, it was suspected that deposits would consist mainly of calcium carbonate with co-deposits of calcium phosphate and magnesium silicate due to insufficient cooling water flow supplied to this unit.

Calcium carbonate deposition is the most common type of scale found in cooling systems with high levels of calcium and alkalinity, especially in areas of the system faced with stressed conditions of high temperatures, high pH and low flow.

Based on this analysis, Veolia recommended an online cleaning using Ferroquest LP7200. Ferroquest is a specialty blend of organic acids that operate at neutral pH, allowing it to be applied without requiring the system to be offline, and with reduced risk of system corrosion and worker safety in comparison with conventional acid cleanings.

In collaboration with the customer’s technical and operations teams, a procedure was designed to clean and remove the cooling water deposits, restoring the performance of the hydrogen units without incurring a production outage.

Ferroquest, was selected as the best path forward as it provided a simple online chemical cleaning solution to mitigate the loss of hydrogen supply while maintaining optimal exchanger machine loading.

Result

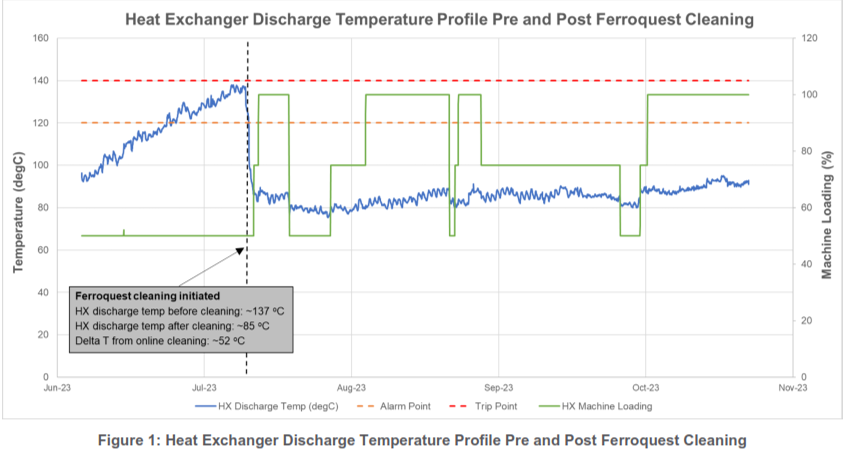

The Ferroquest online treatment successfully removed scale from the heat exchanger surfaces, while avoiding compressor downtime and additional wear and tear on the exchanger bundles. Figure 1 shows that heat exchanger discharge had been increasing to a critical point leading to the cleaning. Within days of conducting the online Ferroquest cleaning, heat exchanger discharge temperature dropped back within normal range as the deposit was removed, without any impact on productivity during the cleaning. These gains were maintained over the following months and no wear on the unit from was observed from the cleaning.

As the Ferroquest cleaning was conducted at neutral pH and online, there was no need for special considerations of hazardous chemicals disposal, unlike when conducting acid cleanings. This also reduced cost and eliminated safety hazards.

Veolia maintained excellent partnership with the hydrogen unit operation team as the Ferroquest application proved successful, restoring exchanger performance, eliminating the need for an outage to mechanically or chemically clean the exchangers, and providing flexibility for the hydrogen unit to run at maximum processing capacity. This financial savings of the application for the customer was estimated to be $300,000 in avoided production loss.

*Trademark of Veolia; may be registered in one or more countries. ©2024 Veolia. All rights reserved. CS1988EN May-24.