Challenge

A US refinery processing a variable crude diet was experiencing hot preheat heat transfer losses, resulting in crude throughput limitations. Despite this limitation, they instigated a plan to pursue a more aggressive crude buying and blending strategy.

The crude diet was primarily composed of Alaska North Slope and Bakken but also contained various proportions of Cold Lake, Alberta Western Blend, Llyod Kerobert, and Bow South crudes. The refinery forecasted the economic benefit of their alternative crude purchasing strategy but remained concerned with the potential acceleration in crude preheat fouling, heat transfer loss, and additional processing issues. These risks threatened the forecasted gains.

Veolia was approached to help develop a solution to manage the negative impacts of existing and future planned purchasing regimes. The goal was to preserve or improve heat transfer, and prevent outages, repetitive cleanings and excess slop generation.

Solution

Veolia’s CrudePLUS* technology, in conjunction with chemical treatment programs, could enable the refinery to evaluate and negate the fouling and instability impact of each crude.

CrudePLUS allows refineries to better evaluate the processing impact and costs associated with each crude purchase in near real-time. Adjustments to the chemical treatment programs can be controlled and optimized based on this data in a feed-forward manner.

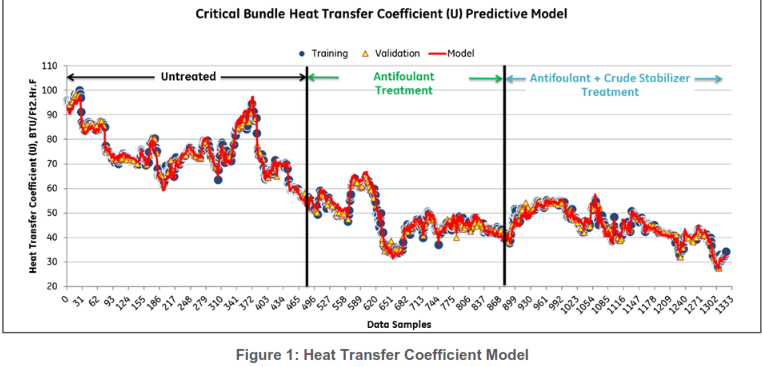

Testing performed on the refinery’s crude oils and blends suggested the best approach would be to add an antifoulant (AF) to the crude unit preheat train and a crude stabilizer (CS) treatment at the crude oil tank farm to treat problematic crudes and blend recipes. To determine the effectiveness of the treatment programs, a heat transfer coefficient model using Veolia advanced mathematical modeling algorithms was built around a critical desalted crude/vacuum bottoms set of bundles. The model incorporates all critical heat transfer predictor variables, and operating data was retrieved from the historian every four hours for the past 460 days to establish a baseline (see Figure 1).

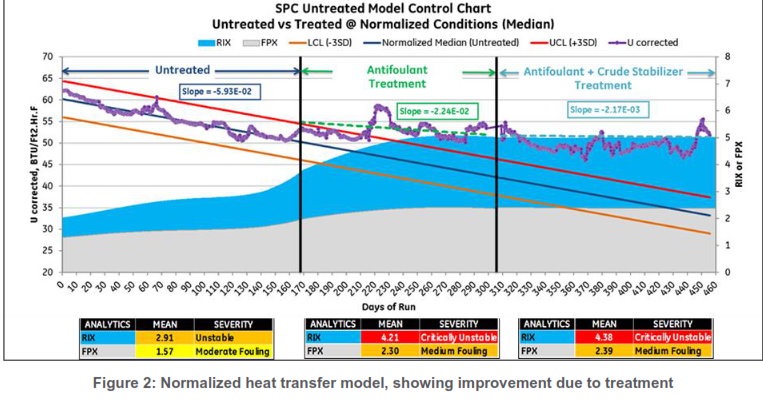

Over the baseline period, the cumulative throughput reduction due to heat transfer capacity erosion was evaluated at $11.6MM/yr. In each subsequent operating period where the AF and the AF+CS were introduced, the model used validation data sets to ensure statistical significance based on the heat transfer coefficient as conditions are changed. Data normalization was conducted for more clarity on the impact of the fouling. (Figure 2).

The procedure implemented to manage treatment of the alternative crude blends was as follows:

- Use CrudePLUS constrained optimization to minimize RIX and FPX as the first mitigation action to optimize crude blends.

- Use CrudePLUS predictive analytics before processing a crude mix to ensure effective chemical treatment.

- Schedule crude blends according to the RIX and FPX results of each blend.

- Manage crude stabilizer injection and dosage per CrudePLUS recommendations to minimize instability episodes and synergistically enhance the performance of antifoulant program.

- Manage antifoulant injection and dosage to mitigate hot crude preheat fouling issues as recommended by Veolia’s service team.

Result

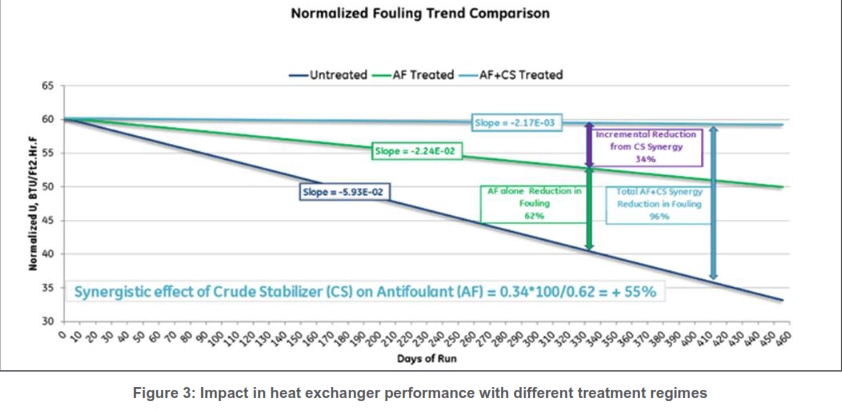

Figure 3 outlines the benefits of Veolia’s mitigating actions to reduce the fouling rate. The graph compares the normalized trends for untreated, treated with AF, and AF+CS. The chart reveals the synergistic effect of CS on AF, as demonstrated by the significant 34% incremental reduction in fouling above the AF-only fouling reduction of 62%. Overall, the heat transfer loss was reduced by 96% with the AF+CS program.

Due to the fouling reduction on the system, bundle cleaning frequency was reduced from 6 bundle cleanings between turnarounds to zero cleanings needed during the most recent operating run cycle.

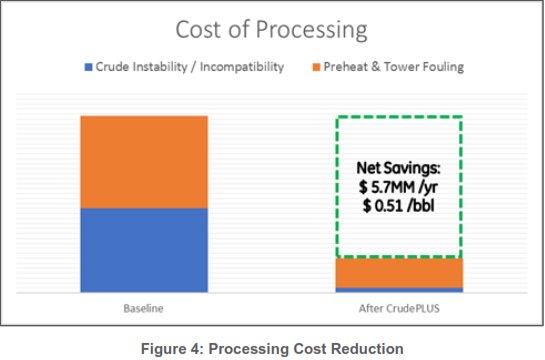

Figure 4 shows the annualized value of the improvements realized by initiating Veolia’s recommendations on this system. The overall impact of the CrudePLUS program is measured by savings through crude preheat fouling cost reduction and reduced slop oil generation. The total net benefit after treatment, including the cost of mitigation actions with targeted chemistry, is an estimated $5.7MM/year or $0.51/BBL of charge.

*Trademark of Veolia; may be registered in one or more countries.