An ethylene plant with a production capacity of 700 KTon per year applied a phosphate-based treatment program combined with caustic to mitigate the corrosion potential in its dilution steam generator (DSG).

The online pH measurement for the dilution steam blowdown (DSBD) controlled the caustic dosage in the bottom of the process water stripper (PWS) to ensure a proper pH in the DSG. This inaccurate and unreliable measurement resulted in poor pH control, high corrosion potential, and a high maintenance frequency on the probes at least once per week.

The online pH-measurement issues were mainly due to frequent fouling of the probes because of the presence of polymers, hydrocarbons, and suspended solids in the sample flow and an inadequate temperature correction at 25°C (77°F).

Veolia’s Quench Water Enhanced System Treatment (QWEST) was introduced, replacing the existing online pH measurement in the DSG to achieve reliable pH control through caustic injection in the bottom of the PWS. QWEST is a monitoring & control system designed to continuously measure the pH and maintain it within the defined range by adjusting the chemical injection. It can provide pH control on different systems, such as quench water towers and dilution steam generators.

Reliable pH control within set boundaries is essential to ensure proper oil separation while preventing corrosion, resulting in improved operations, asset life, and profitability. A pretreatment system on the QWEST provides a clean and stable sample flow for accurate pH monitoring with minimal maintenance and downtime. The pH measurement is utilized to directly control the chemical feed pump or connection to the DCS for immediate dose response. The key features of QWEST supporting an accurate and reliable pH measurement/control include:

- Sample pretreatment – sample cooler, filter system for removing solids, coalescer to remove free hydrocarbons

- Redundant pH probes with an internal crosscheck to detect deviations in pH measurement

- Connection to InSight* and/or the customer’s DCS system

Result

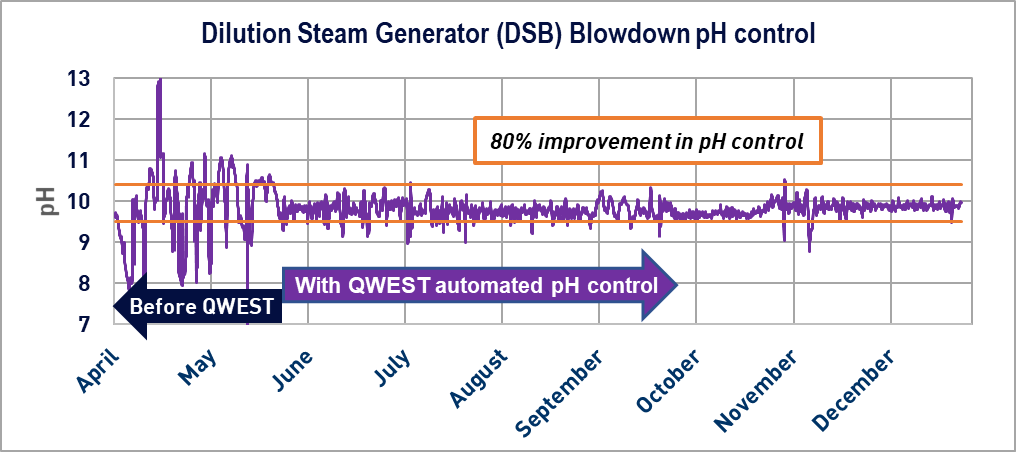

The QWEST unit proved to be an accurate and reliable pH controlling device reducing pH fluctuations. This helped control the pH from the DSG within the predefined pH limits through the online adjustment of the caustic injection bottom PWS (Figure 2). Therefore, minimizing the corrosion potential in combination with the Veolia phosphate-based treatment program. This resulted in:

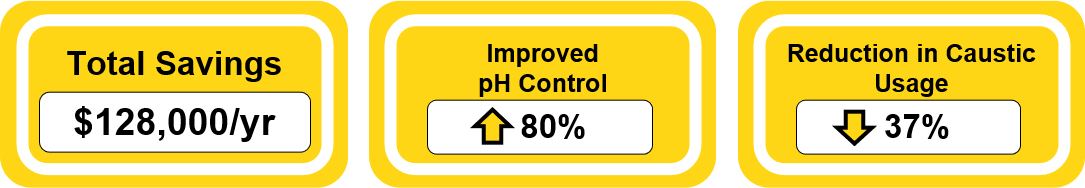

- Improved coordination of pH/PO4 by 80%, reducing the corrosion tendency in the DSG.

- Reduced caustic usage of 40%, valued at $24,000 per year.

- Reduced maintenance interventions on the pH probes from once per week on average to once per quarter (preventative maintenance), valued at $104,000 per year.

- Reduced total operational cost by $128,000 per year.