Challenge

A North American industrial chemical facility needed to significantly reduce phosphorus usage to meet new local regulatory restrictions, which required an 80% reduction in phosphorus and restricted the use of metal-based additives. Phosphate is a critical water treatment component that provides mild steel corrosion control in cooling water systems and prevents the breakdown and failure of critical systems. In many systems, zinc and other metals can also be added to enhance corrosion control with or without the use of phosphate.

The new regulation would require the implementation of a phosphorus removal system if the traditional phosphate-based cooling water program was not replaced. Moreover, as indicated, beneficial metal additives such as zinc could not be used as a replacement to phosphorus chemistry.

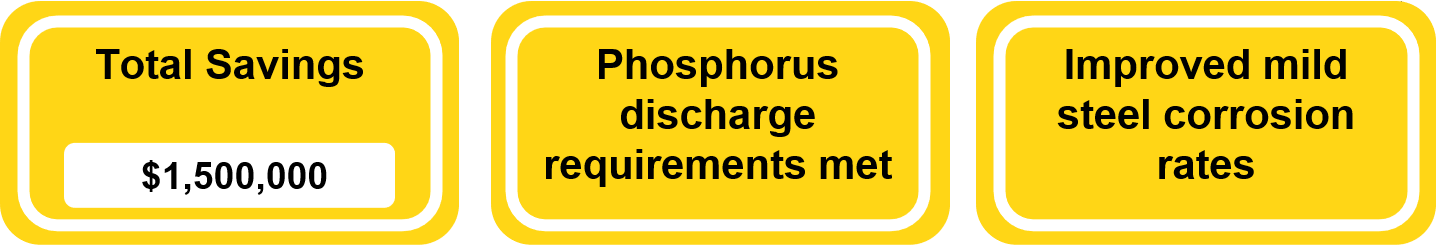

Faced with a $1.5M capital investment requirement plus operating expenses and increased operational complexity, the customer turned to Veolia to provide alternative options that would help meet the new discharge regulations without the need for an expensive capital project, while achieving the desired cooling water system performance and reliability.

Solution

To reduce/eliminate the use of phosphorus1 and metal additives, Veolia’s E.C.O.Film non-phosphorus technology was implemented to control mild steel corrosion, deposition, and yellow metal corrosion.

E.C.O.Film enables operators to maintain or improve corrosion rates, reduce or eliminate deposition risk from phosphate salts (e.g., calcium phosphate), reduce the biological nutrient load of the cooling water and effluent water, and assists customers in meeting stricter phosphorus discharge limits.

Result

The implementation of E.C.O.Film technology:

- Saved the customer $1.5M in capital costs

- Eliminated the need for additional operating expenses associated with a new phosphorus removal system

- Allowed for the new, stricter phosphorus discharge requirements to be met

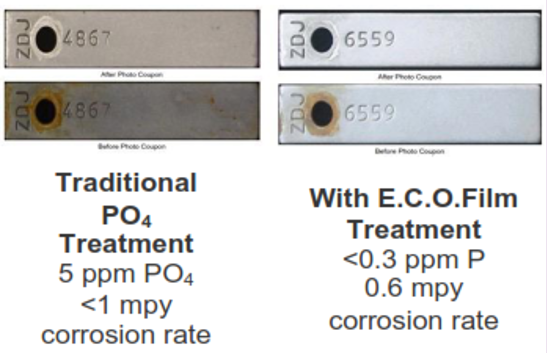

- Maintained mild steel corrosion rates at <1 mpy while reducing phosphorus to <0.3 ppm P in the circulating water (Figure 1)

Figure 1: Representative mild steel coupon corrosion rates (42-day exposures)

1 May contain trace amounts

*Trademark of Veolia; may be registered in one or more countries.