Challenge

A Midwestern power plant routinely experienced algal growth in its cooling water system and settling basin, which led to TSS permit exceedances and potential fines. A key part of the circulating cooling water treatment program was phosphorus-based chemistry for scale and deposit control. Since phosphorus is a limiting nutrient for microbiological activity and algal growth, the customer indicated that if the phosphorus added to the cooling water system was eliminated, then the algal growth/TSS challenge would be mitigated. The nonphosphorus chemistry would still need to provide excellent scale and deposit control to ensure that the condensers stay clean and depositfree.

Solution

The traditional phosphorus-based scale/deposit inhibitor feed was discontinued, and Veolia’s new proprietary non-phosphorus1 E.C.O.Film (Engineered Carboxylate Oxide) technology with Surface Film Formation Catalyst (SFFC) was used. The oxidizing biocide/nonoxidizing biocide program was continued for biological control.

E.C.O.Film enables customers to treat cooling water, maintain or improve corrosion rates, control scale-deposit, and reduce or eliminate deposition risk from phosphate salts (e.g., calcium phosphate). E.C.O.Film can also reduce the biological nutrient load of the cooling water and the effluent water, and assist in meeting stricter phosphorus discharge limits, among other benefits. In this case, the key function of E.C.O.Film was scale and deposit control while assisting the mitigation of algal growth and TSS limit exceedances.

A holistic offering was implemented and included the E.C.O.Film chemistry and an extensive instrument-equipment package.

The E.C.O.Film feed was automated with feed and control via online fluorometer measurement. A TrueSense* MonitAll* deposition monitor was used to emulate the condenser and to track deposition in real-time. For continuous online data, performance trending, and analysis, Veolia’s InSight* asset performance management system was used.

A field trial was carried out to demonstrate the performance with E.C.O.Film from a scale and deposit control perspective with the expectation that eliminating the phosphorus fed to the cooling water system would ultimately lead to algal growth mitigation and the achievement of TSS limit requirements. Following the successful field trial, E.C.O.Film was implemented on all the circulating cooling water towers at the power plant, with high-level results reported next.

Result

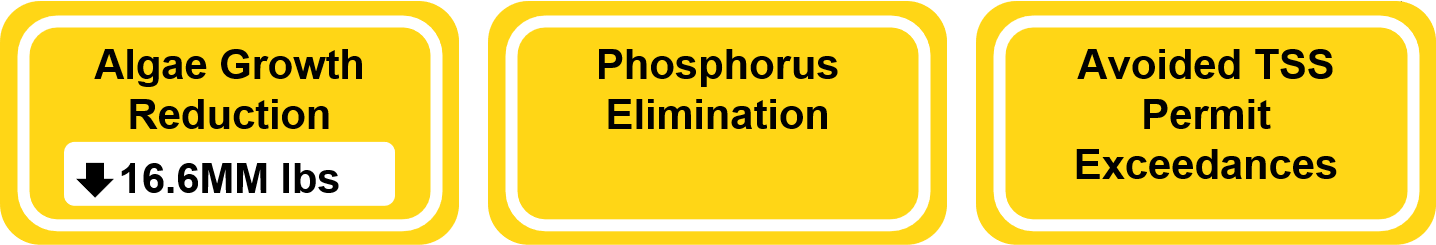

As a result of the E.C.O Film technology, the power plant met the required scale and deposit control performance of the condensers and other heat exchange equipment, as well as the required overall system performance, including a very positive impact on algal growth mitigation and the resultant TSS contributions. The implementation of E.C.O.Film technology:

- Eliminated phosphorus addition

- Reduced the potential for 16.6MM lbs of algae growth

- Avoided TSS permit exceedances

- Maintained the cleanliness of the problematic settling basin (via visual inspection and chlorophyll values)

- Demonstrated real-time deposit control performance via the TrueSense MonitAll deposition monitor.

1 May contain trace amounts

*Trademark of Veolia; may be registered in one or more countries.