Challenge

A Canadian ethanol producer was experiencing organic fouling in a beer column, which was impacting productivity. The column would significantly foul and plug-off the tower every 6 months, forcing the plant to de-rate to maintain operation. To flush the solids though the column, water flushing would be needed almost daily to lower the differential pressure (DP) and maintain desired beer feed to the column. Annually, the unit would be shut down and cleaned out manually by shoveling out the accumulated solids. This resulted in high maintenance costs, lost production time and risk to personnel.

Solution

The problematic deposit was sampled on two separate occasions to determine the type of contaminant at fault. Having confirmed it was an organic foulant, Veolia proposed the use of a FoodPro* deposit control aid specifically formulated to address organic deposition.

In partnership with the plant’s operating team, a process baseline was established prior to initiating the treatment. Veolia also recommended operational changes that allowed for a more efficient beer column washing. Dosage was increased incrementally until data indicated that increasing differential pressure across the beer column was minimized and that fouling was mitigated by the treatment.

Result

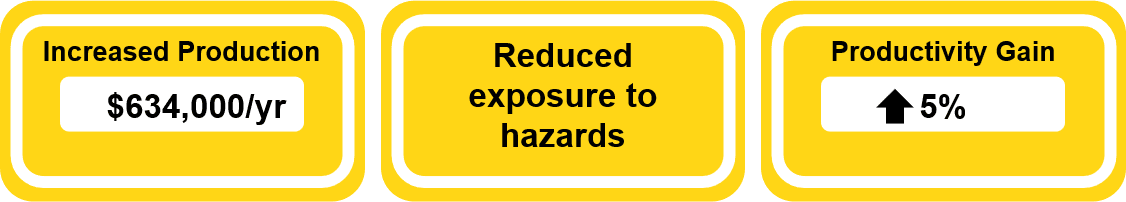

With the help of the FoodPro organic deposit control aid, the plant was able to increase production by 20,000 liters of ethanol per day – 1.9MM gallons of additional ethanol on a yearly basis, setting a production record. This represented a productivity gain of ~5%, a value estimated at $634,000 based on ethanol market value.

Operating with reduced water washes and fewer manual cleanings on the beer column also reduced the health & safety risk related to confined space entries and exposure to other hazards. It also freed up plant operations to focus on other projects and plant operations