Challenge

A Midwestern power plant needed to significantly reduce the phosphorus contribution of their cooling water treatment program to meet new local regulatory restrictions, which were implemented to safeguard the river and downstream water bodies.

The customer turned to Veolia to provide an alternative solution that would remove phosphorus from the effluent water while maintaining mild steel corrosion rates and overall system performance without a significant capital investment for an engineered phosphorus removal system.

Solution

The traditional phosphorus-based mild steel corrosion inhibitor feed was discontinued and Veolia’s new proprietary non-phosphorus1 E.C.O.Film technology was used. A complete monitoring & control solution was provided to automate precise testing, feed, and control of the E.C.O.Film chemistry. Continuous online data and performance trending was provided using Veolia’s InSight* asset performance management system.

E.C.O.Film enables customers to treat cooling water, maintain or improve corrosion rates, reduce or eliminate deposition risk from phosphate salts (e.g., calcium phosphate), reduce the biological nutrient load of the cooling water and effluent water, and assist our customers in meeting stricter phosphorus discharge limits.

Result

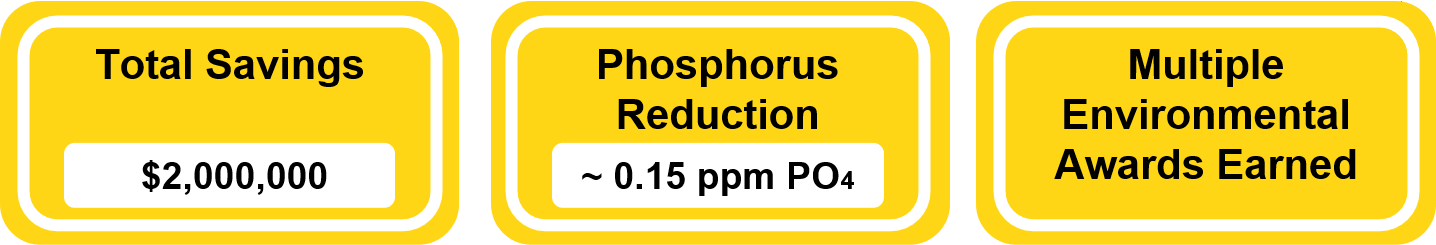

As a result of the E.C.O Film technology, the power plant met their desired mild steel corrosion rates and overall system performance was achieved. The phosphorus content in the cooling water was reduced to ~0.15 ppm PO4, allowing the much stricter phosphorus discharge regulations to be met. In addition, the power plant earned notable environmental awards driven by the reduction in phosphorus discharge to the compromised water bodies. The implementation of E.C.O.Film technology:

- Saved the customer ~$2 million in capital costs

- Eliminated the need for additional operating expense and complexity associated with a phosphorus removal system

- Allowed for successful operation without any phosphate-based additives

- Maintained control of mild steel corrosion and provided excellent overall system performance.

1 May contain trace amounts

*Trademark of Veolia; may be registered in one or more countries.