Challenge

For many years, the main cooling tower at a combined cycle power plant in the Caribbean had been treated successfully using a phosphate-based alkaline chemical treatment program. However, increasing restrictions on phosphate discharge and limitations on raw well water consumption led the plant to seek alternative solutions.

Another concern was the rising cost of acid used for pH control in the cooling tower. This plant was forced to use hydrochloric acid instead of sulfuric acid because the wastewater facility could not tolerate excessive levels of sulfate in the plant discharge. Hydrochloric acid being much more expensive than sulfuric acid, this explained that the plant was looking for ways to reduce acid consumption.

Solution

The traditional phosphorus-based carbon steel corrosion inhibitor feed was discontinued and Veolia’s proprietary non-phosphorus1 E.C.O.Film technology was used. A complete monitoring & control solution was provided to automate precise online testing, feed, and control of the E.C.O.Film chemistry. Continuous online data and performance trending was provided using Veolia’s InSight* cloud-based asset performance management system.

E.C.O.Film enables operators to treat cooling water without the use of phosphorus or heavy metals while effectively controlling corrosion rates, reducing risk of deposition from phosphate salts (e.g., calcium phosphate), reducing the biological nutrient load and algae growth, and meeting increasingly strict phosphorus discharge limits.

Result

The plant implemented the E.C.O.Film program and has been operating for nearly two years. Over this time, asset protection and operational reliability have been excellent. Corrosion rates on carbon steel have averaged 2.6 mils/year (mpy), which aligns with results obtained with the traditional phosphate program and meets the KPI limit of 3.0 mpy or lower. Condenser cleanliness has been maintained with no loss of vacuum or evidence of fouling or scaling noted during inspections.

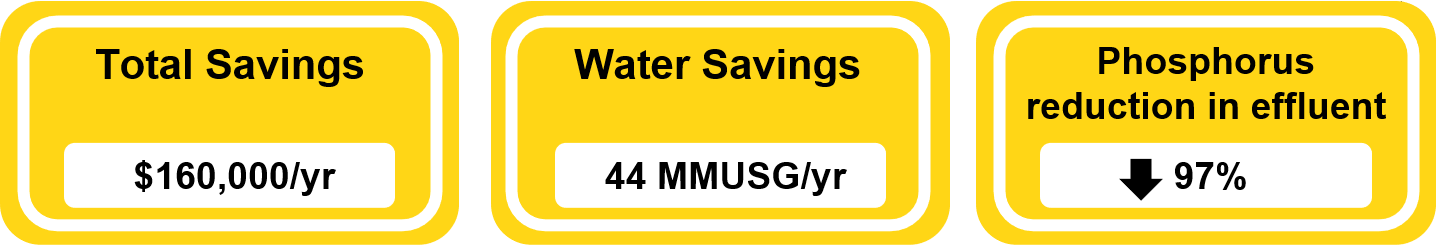

Without the risk of phosphate deposition and high requirement of acid, the E.C.O.Film program has allowed the plant to operate at higher cycles of concentration. Cycles were increased from approximately 3.5 to 6.5, which reduced raw water consumption by about 44 MMUSG per year, and reduced wastewater discharged by an equal amount. Additionally, there has been a 97% reduction in phosphorus in the plant discharge as compared to the previous phosphate-based cooling water treatment program, helping the plant to meet tightening phosphorus discharge limits.

As a result of operating with reduced blowdown, chemicals usage dropped substantially with the implementation of the E.C.O.Film program. Not only does this result in reduced costs for the deposit and corrosion control treatment but also for hydrochloric acid. Overall, the plant estimates that there has been savings of $160,000 per year in total chemical treatment costs resulting from using the E.C.O. Film treatment program on their cooling system.

*Trademark of Veolia; may be registered in one or more countries.