Challenge

ASM is a leading global supplier of semiconductor wafer processing equipment present in the US and 14 other countries around the world. The company delivers innovative technology solutions to the world’s leading semiconductor manufacturers while maintaining a strong focus on doing so through reliable and sustainable actions in its own operations and value chain. ASM is committed to accelerating sustainability initiatives – with an aim for Net Zero operations by 2035.

In 2018, ASM’s US operations team in Phoenix, Arizona, met with Veolia to investigate means to reduce their environmental footprint, especially concerning water conservation. The ASM facility is located in a region in which water usage is scrutinized. Given ASM’s commitment to improving and innovating sustainability across the globe, Veolia and ASM partnered on a multi-year project to reduce ASM’s water usage at is Phoenix facility.

Solution

The audit conducted by the Veolia team in partnership with ASM led to the conclusion that one of the biggest water users at the plant, the cooling tower system, could have its operation optimized to reduce the amount of water it required to run.

Cooling systems are essential to many industrial operations to provide production equipment and comfort cooling. The water circulates throughout the facility in a complex piping arrangement, collecting heat from the various areas and bringing it back to the cooling tower. There, the heat is dissipated into the atmosphere by evaporating a portion of the warm water. Evaporation causes dissolved solids and minerals in the remaining water to concentrate. To prevent these minerals from forming deposits that would be problematic for the system’s reliability and productivity, some of it is discharged to the city sewer.

The Veolia team determined that the cooling tower could reduce their amount of water usage by cutting back their discharge flow, but this would result in an increase in dissolved solids it contained.

Veolia supported ASM to present to the municipality its plan to reduce water usage of the cooling tower and to explain how these water savings were an improvement, despite a possible increase in dissolved solids.

Result

The ASM facility was allowed by the municipality to modify its operation, and the pm10 permit that was limiting its cooling tower operation to 2 cycles of operation was revised so they could operate at 3.25 cycles.

This increase in cycles of concentration meant that the cooling water system daily water consumption dropped from 28,000 USG to 9,000 USG, a reduction of more than 60%.

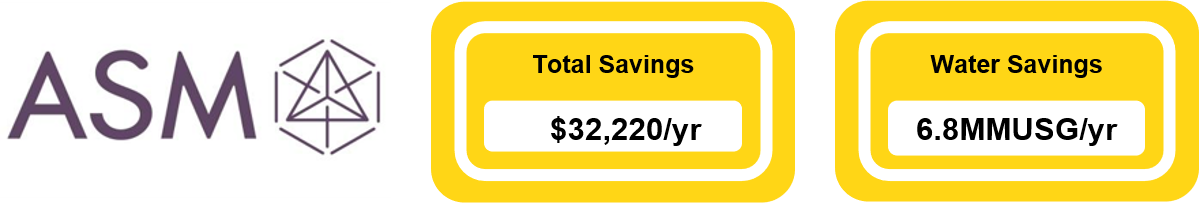

Over the course of a year, the ASM facility in Phoenix now saves more than 6.8 MMUSG. For this great contribution to the environment and their community, Veolia recognized ASM with one of its Return On Environment Award.

The reduction in water and chemical treatment usage for the cooling system saved ASM a total of approximately $35,220.

Learn how Veolia touches all aspects of the Circular Economy within a Semiconductor site.