A Midwestern steel producer was experiencing significant O&G (oil & grease) fouling of their rolling mill media filters. The fouling was so severe that the filters had to be bypassed due to inadequate flow. Consequently, the downstream rolling mill spray nozzles were plugging, leading to inadequate cooling of the final steel product and associated quality issues.

Previous attempts to chemically clean the media were unsuccessful and the mill was advised that the only option would be to do a full replacement of the media in their eight filters at a significant cost.

Veolia examined the existing media filter operation and determined the challenge was similar to what had been observed at other steel mills with severe O&G fouling. With decades of experience supporting other filter operations in contact water systems, Veolia developed an offline cleaning method to recover the filter performance that has proven successful in many steel mills. This strategy incorporates patented cleaners and a comprehensive procedure to provide an enhanced backwash cycle.

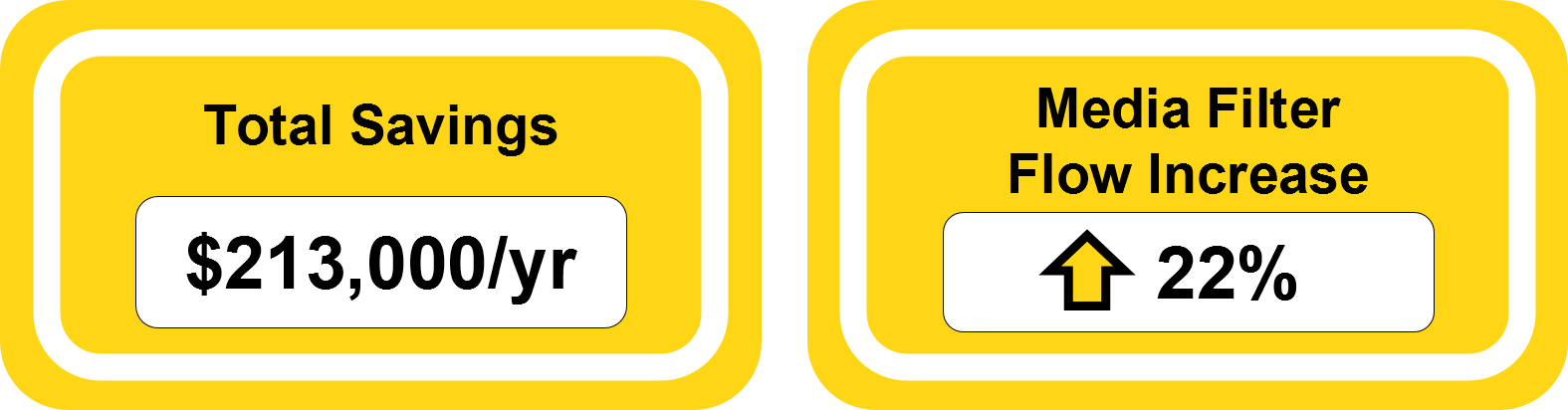

Result

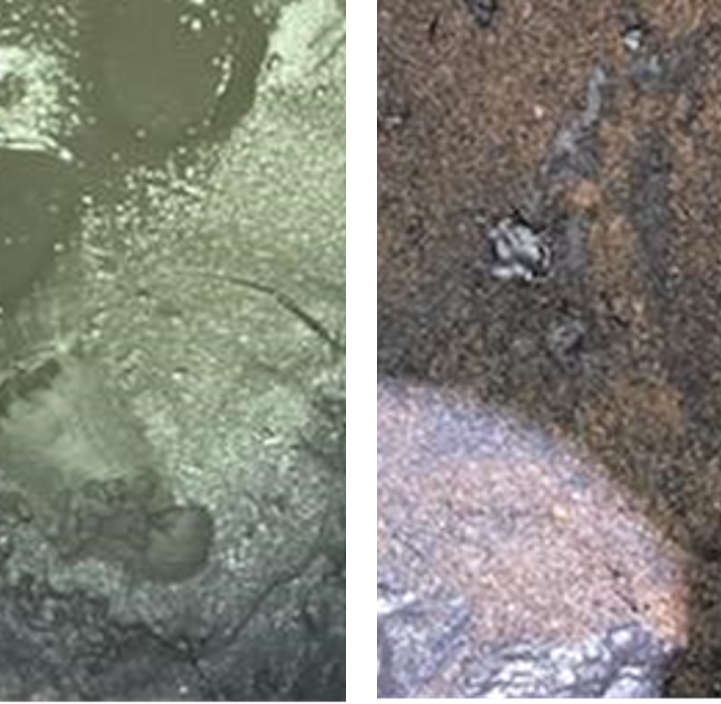

Following the successful cleaning (Figure 1), the filtered water flow increased by ~22%. This allowed the mill to no longer bypass the media filters and the water quality to the spray system increased significantly. This prevented the replacement of the media, savings estimated at $213,000.

More importantly, the rolling mill spray water reliability improved, and the risk of off-spec product associated with inadequate spray water was eliminated.

Figure 1: Filter media covered in O&G before cleaning (left) and after cleaning (right)