Challenge

A wet corn milling facility producing ethanol contacted their cleaning services company to develop a plan to acid-clean one of their storage tanks. The material to be removed from the tank’s bottom and walls was composed of activated carbon, diatomaceous earth, magnesium hydroxide solids and organic solid from the corn milling process.

Previous acid cleanings of this tank had resulted in health and safety complaints from the surrounding community, specifically due to odors and the detection of hydrogen sulfide (H2S) in the surrounding atmosphere. The solubility of H2S reduces in acidic conditions, making it volatile, and can be harmful when breathed even at low concentrations. The plant wanted to ensure efficient cleaning without further risks and complaints from the community and its workers.

Solution

To prevent H2S emissions during the tank cleaning, Veolia recommended adding ProSweet OC2543 into the tank slurry material before the cleaning was initiated. This additive is a patented non-amine-based sulfide scavenger that complexes malodorous H2S and mercaptans in water and wastewater streams. ProSweet OC2543 reacts with H2S and mercaptans in solution to form stable, liquid phase reaction products that are non-volatile in acidic conditions.

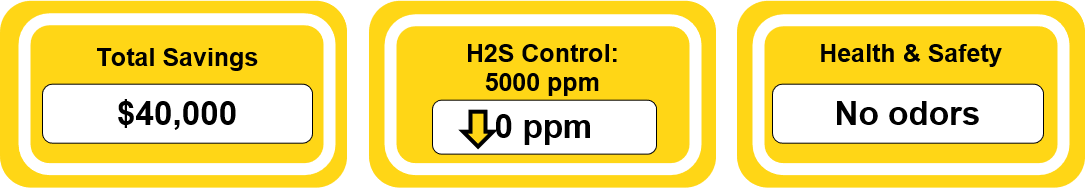

As ProSweet OC2543 was mixed with the tank solution on the first treatment, the H2S concentration measured in the tank decreased from 5000 ppm to 0 ppm (non-detectable). To control any remaining odors that may have been present after the H2S scavenging, Veolia recommended utilizing ProSweet OC2554. ProSweet OC2554 is a blend of essential oils and surfactants formulated to provide mitigation of a wide variety of non-sulfide nuisance odors. The ProSweet OC2554 was added to the vacuum disposal truck during the cleaning and removal of the tank sludge to control any remaining odors.

By utilizing the combination of ProSweet products, the cleaning services company was able to safely clean the tank without incident.

Result

The Veolia 2-product chemical solution allowed for the successful cleaning of the tank without any incidents and ensuring the safety of the workers and surrounding community. With H2S emissions and odors fully controlled, the cleaning was completed 2- days ahead of schedule resulting in savings associated with labor and equipment of $40,000.