Challenge

Bush Brothers & Company (Bush) is a family-owned corporation best known for its Bush's Best brand of canned baked beans.

In 2014, after nearly a decade of operation, Bush began the process of upgrading their existing wastewater treatment system at their facility in Dandridge, Tennessee.

The original system was stressed to meet current demand and droughts had begun to limit well water supply to the facility, which highlighted the need for additional water sources. Bush wanted to improve their infrastructure to meet the actual and future requirements and improve sustainability with water reuse.

Solution

Bush’s improved and expanded Process Water Reclamation Facility (PWRF), that includes:

- Screening

- Equalization

- Anaerobic contact process with DAF separation

- Biological nutrient removal (BNR) process using Membrane Bioreactor (MBR) technology including biological phosphorus removal, denitrification, and nitrification

- A portion of the MBR permeate goes to a reverse Osmosis (RO) system for reuse as plant cooling tower makeup and boiler makeup

- The balance flows by gravity to an effluent holding pond prior to land application

Result

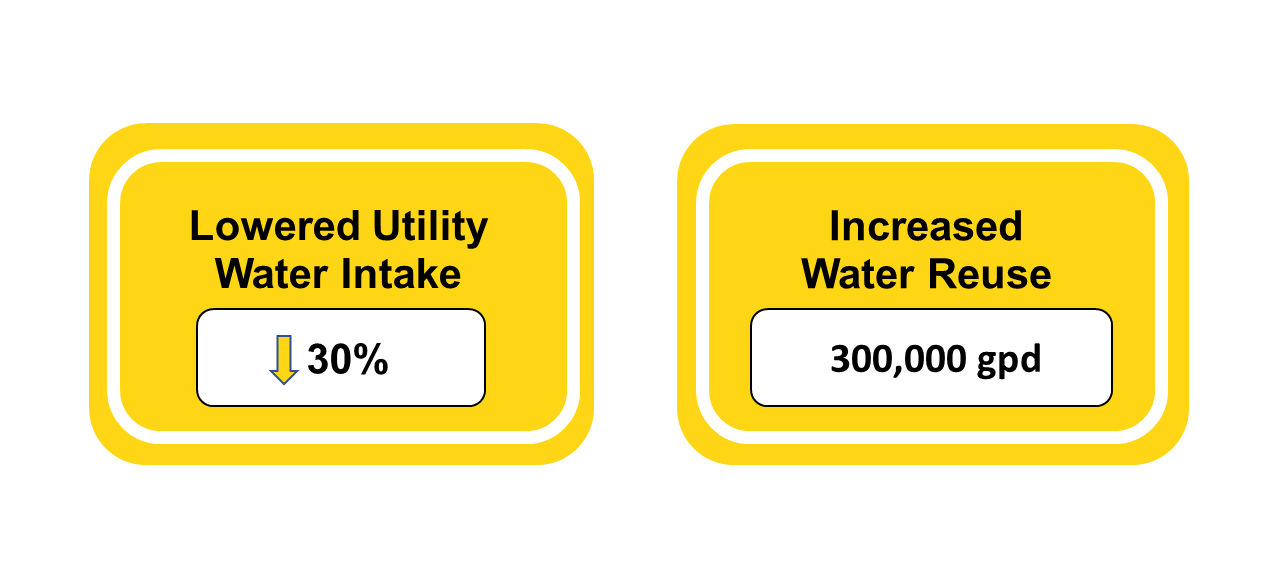

The ZeeWeed MBR system, provided by Veolia | Water Tech, enabled reuse of 1,700 m3 /day (300,000 gpd) of treated effluent water, which decreased the plants utility water intake by 30% and helped mitigate the risk of water shortage.

The ZeeWeed MBR technology is a critical part of the solution for meeting both the water reuse and stringent discharge quality needs. The MBR allows downstream RO membrane processes, used for final water treatment step, to operate very efficiently and with minimal maintenance. Because it combines several process steps (solids/liquid separation and postfiltration) and operates at higher mixed liquor concentrations, the ZeeWeed MBR also offers significant reductions in footprint and operational complexity.

The water reuse project implemented at Bush represents multiple sustainability benefits, including reduced environmental BOD and nutrient emissions, production of biogas fuel and cattle feed, and providing irrigation of cover crops. The high-quality effluent of the MBR also makes it suitable for several utility reuse applications like, cooling tower makeup and boiler makeup.

As a result of this work, Bush was the recipient of the Water Environment Federation (WEF) 2022 Industrial Water Quality Achievement Award, which recognizes innovative design and operation of an industrial wastewater, pretreatment, or source prevention program.

Bush’s PWRF is a great example of industrial wastewater treatment and an appealing story that demonstrates an upgrade to increased demand and a highly sustainable approach targeting beneficial water reuse applications. It serves as an example for other industrial facilities seeking to maximize reuse and minimize environmental footprint.