Challenge

The Yorkville-Bristol Sanitary District (YBSD) wastewater treatment plant in Yorkville, Illinois, serves a population of 22,000 and discharges to the Fox River. The plant is rated for a design average flow of 3.62 MGD (13.7 MLD). Prior to 2017, the facility was a singlestage nitrifying activated sludge system.

Population growth and the arrival of new industrial contributions were anticipated to result in the facility exceeding its rated organic capacity. At the same time, YBSD had to comply with a new total phosphorous limit of 1 mg/L. This situation required the plant to be upgraded to increase organic treatment capacity and implement phosphorous removal.

The existing site is footprint constrained; a conventional upgrade would require construction of a separate treatment plant on adjacent property. YBSD sought a retrofit solution that would minimize capital expenditure and avoid significant civil modifications to the facility while accelerating the implementation schedule by avoiding the time required to permit and construct a new plant.

Solution

YBSD chose to upgrade the plant with Veolia’s ZeeLung technology in combination with enhanced biological phosphorous removal (EBPR) for the following reasons:

1. 45% increase in organic treatment capacity in the existing bioreactor volume

2. 75% capital cost savings compared to conventional upgrade

3. Quick implementation with design & construction in 18 months

4. Synergy between ZeeLung and biological phosphorous removal

5. No net increase in energy consumption, despite the increased capacity and more stringent effluent limit

ZeeLung technology employs an innovative gas transfer media to deliver oxygen to a biofilm that is attached to the media surface. Oxygen is delivered to the biofilm by diffusion through the media, reducing the energy required for oxygen delivery by up to four times compared to conventional aeration. Immersing ZeeLung cassettes into mixed liquor increases the inventory of biomass in a treatment system, thereby intensifying the biological treatment process and enabling increased organic load to be treated in existing biological reactors.

Prior to the ZeeLung upgrade, the YBSD activated sludge system was configured with two parallel treatment lanes, each with five aerobic reactors in series. The upgrade involved modifying the first tank to an anaerobic zone (to promote the growth of phosphorous accumulating organisms) and the second tank to an anoxic zone populated with ZeeLung cassettes. The ZeeLung cassettes support a nitrifying biofilm that enables simultaneous nitrification & denitrification to occur in the anoxic zone.

Result

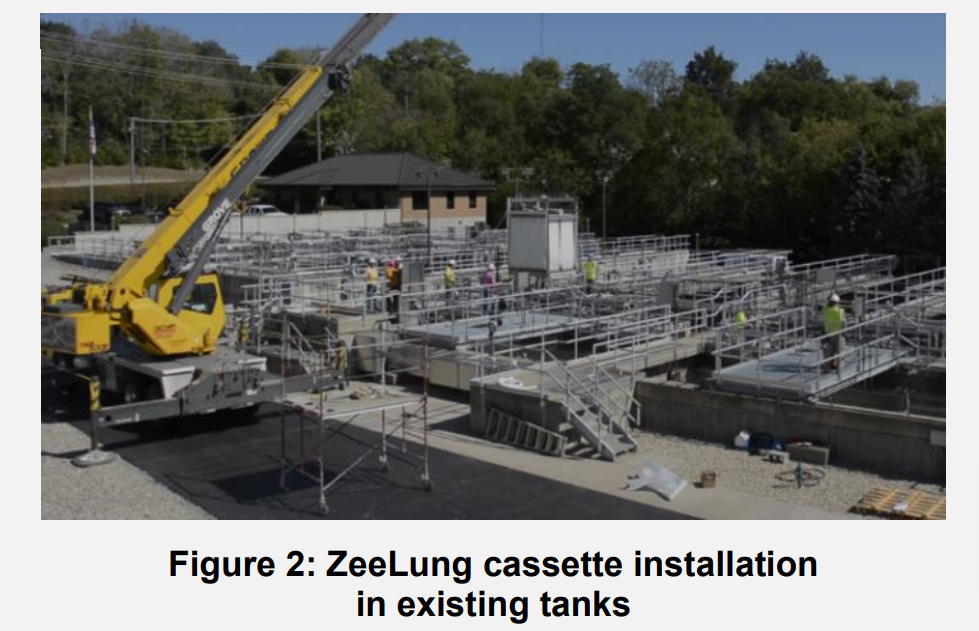

Phase 1 of the ZeeLung upgrade, which involved retrofitting one of the two treatment lanes, was commissioned in 2017 (Figure 2).

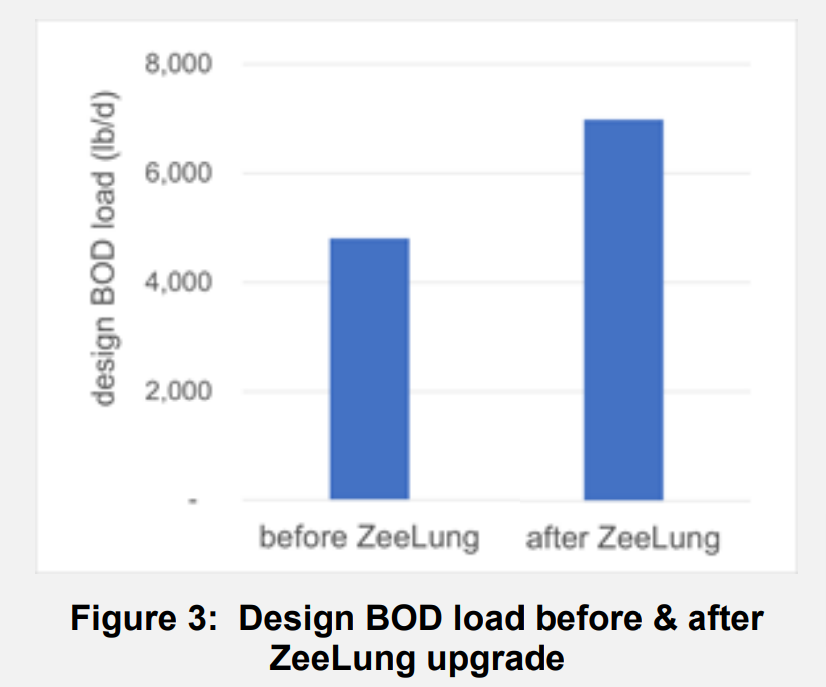

The ZeeLung upgrade increases the design organic treatment capacity of the plant by 45% at the full implementation (Figure 3).

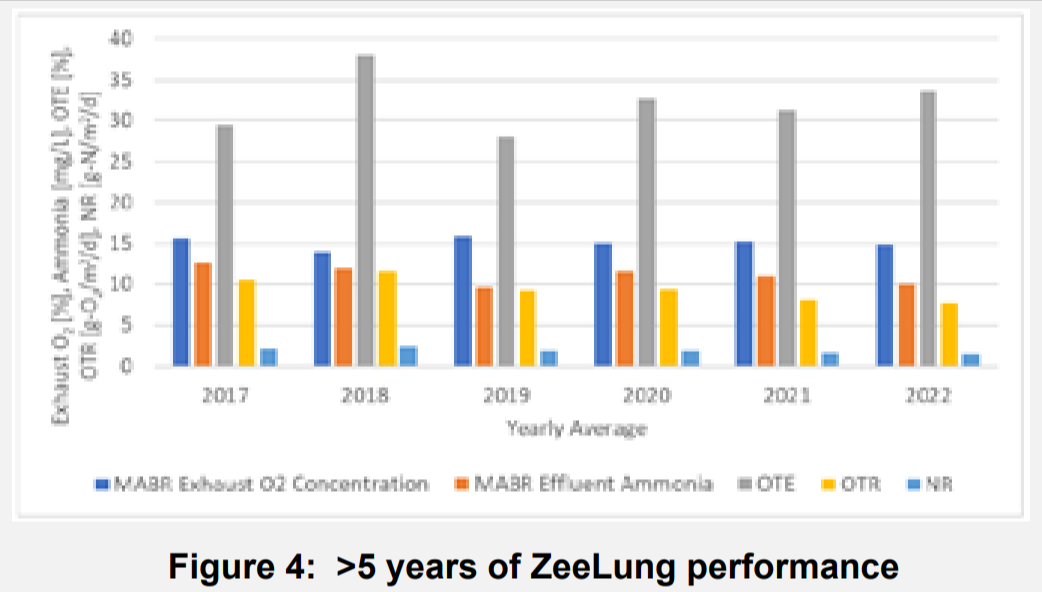

Figure 4 reports the performance of the ZeeLung system through the first 5 years. ZeeLung oxygen transfer and nitrification performance has been consistent through 5 years of continuous operation.

The improved removal of nitrogen by ZeeLung has a positive impact on phosphorous removal by reducing the nitrate load to the anaerobic zone. Phosphorous removal performance at YBSD is summarized in Figure 5.