Challenge

The Town of Creemore and the surrounding area were using individual septic systems to handle wastewater and truck-away waste sludge for further treatment. The town’s major industry, the Creemore Brewery, also trucked wastewater for treatment and disposal. The community was concerned about the number of septic tanks, undersized leaching beds, and holding tanks. Wanting to protect the underground aquifer from contamination and add value to local properties, they decided it would be beneficial to build a centralized wastewater treatment plant to handle the combined municipal sewage and industrial wastewater.

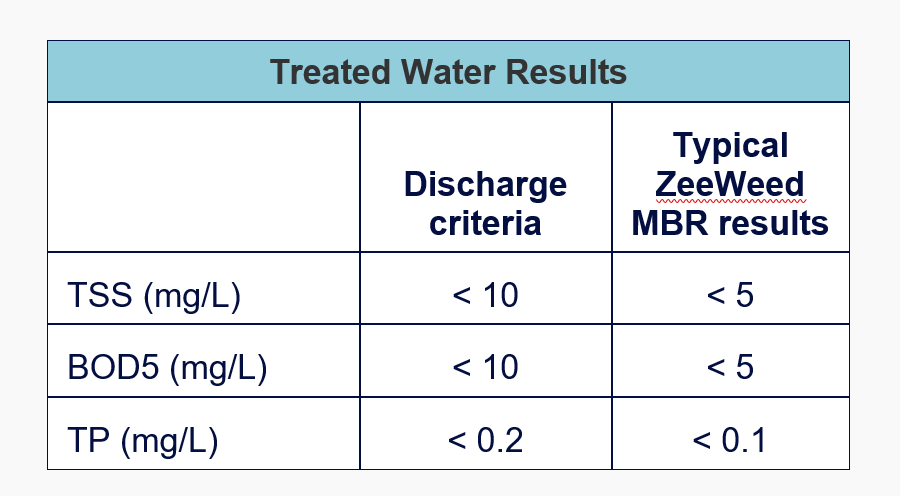

The local residents proposed a number of conditions for the new plant. They wanted it to be unobtrusive, affordable to construct and operate, able to accommodate future expansion, and they did not want to negatively impact the surrounding environment. Since the treated effluent was to be discharged to a sensitive cold-water fish habitat, stringent effluent discharge parameters were targeted.

After a thorough review of the options available to the town, it was decided that Veolia’s ZeeWeed* MBR was the best available technology and could produce treated effluent of such high quality that it could be discharged directly into the sensitive Mad River

Solution

In order to blend the new plant with the rural scenery, the exterior of the building was designed to look like a dairy barn. To reduce capital and operational costs for ventilation, one end of the barn structure was opened and a shallow breezeway was created along a side wall to provide natural ventilation.

The treatment process consists of an influent pumping station complete with an automatic fine screening system, ZeeWeed membrane filtration, which includes anoxic and aerobic zones, ultraviolet (UV) disinfection, effluent re-aeration chamber, and outfall to the Mad River.

Result

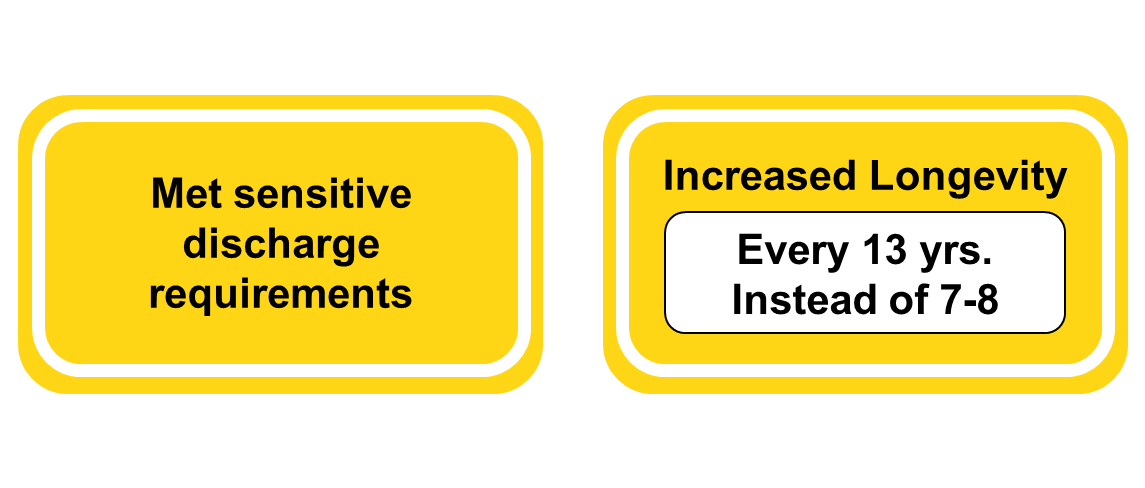

The Creemore Wastewater plant was commissioned in 2000. The completion of the original ZeeWeed MBR plant enabled the Town to be unobtrusive, affordable, accommodate future expansion, and meet sensitive discharge requirements needed for the surrounding area.

In 2000, membranes in an MBR environment were expected to have a life expectancy of 7-8 years. Far exceeding initial expectations, the original membranes were replaced in 2013. This longevity on the first set of membranes saved significant money for Creemore with the cost of the membranes spread over 13 years vs 7-8 years.

In 2017, Creemore investigated economic advantages and additional technical flexibility and experimented with an alternative technology, installing four cassettes of non-Veolia membranes into one of the two trains.

While the competitor membranes worked well initially, within one year of operation the performance of the competitor membranes began to fail while the original train of 7-year-old ZeeWeed membranes continued to demonstrate superior performance. The competitor membranes were shortly replaced with ZeeWeed Membranes.

Operating again with an entire ZeeWeed membrane contingent, the plant plans to continue exclusively with ZeeWeed membranes as they’ve demonstrated a superior ability to maintain the required design flow and performance during an extended filtration life.