With growing concerns about water shortages, and a population that is expected to grow rapidly, the City of American Canyon required a wastewater treatment facility that would meet their current and future needs.

At the time, the City’s wastewater was sent to a regional wastewater treatment facility, and the City determined the best option was to construct a new City owned facility and wanted to reuse a portion, if not all, of the treated effluent from its wastewater treatment plant for vineyard and golf course irrigation to reduce the amount of fresh water drawn from the Napa River. To do so, the plant would have to achieve stringent California Title 22 water reuse standards.

Working with the project’s consulting engineer, HydroScience Engineering, the City of American Canyon reviewed several treatment options, and decided that membrane bioreactor (MBR) technology would best suit its needs. In July 2000, the City selected ZENON Environmental Corporation (a wholly owned business of Veolia | Water Tech), to supply a ZeeWeed* MBR system to treat an average dry weather daily flow of 2.5 MGD (9,464 m3/d), and average wet weather flow of 3.75 MGD (14,200 m3/d). The original system was commissioned in 2002.

ZeeWeed MBR combines immersed membrane fibers with activated sludge to produce superior quality effluent. The membrane forms a physical barrier to biomass, bacteria and viruses, retaining them in the process tank, while allowing high quality effluent to pass, ideal for reuse applications.

The ZeeWeed MBR system is modular. Individual ZeeWeed membrane modules are combined to form cassettes to meet the required treatment capacity. The advantage to a growing city is that plant expansion can be in stride with actual community growth, drastically reducing up-front development costs.

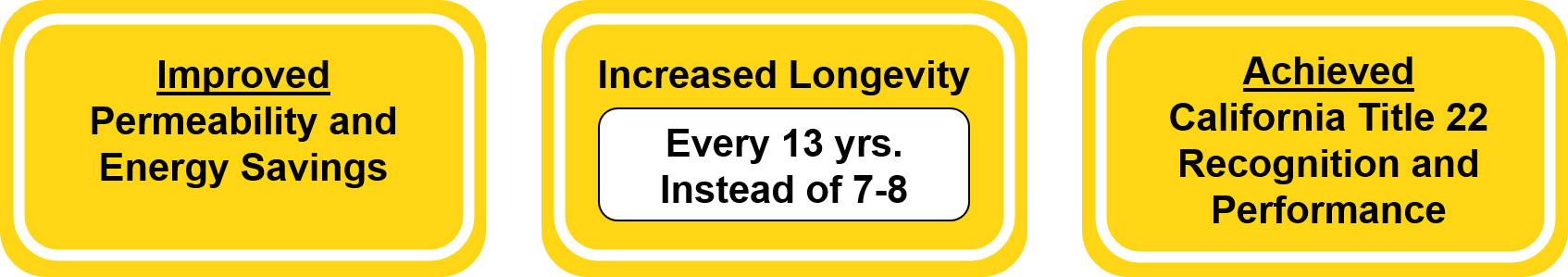

At the time, membranes in an MBR environment were expected to have a membrane life of 7-8 years. Far exceeding initial expectations, after over 13 years, the plant installed their first set of replacement membranes in 2015. The city determined the best option was to upgrade the MBR portion of their plant with the latest Veolia ZeeWeed MBR system using ZeeWeed ZW500D membranes.

Veolia replaced all four trains with ZeeWeed MBR 500D technology. The increased module surface area and improved permeability of the upgraded membranes reduced the overall number of cassettes and lowered energy use while staying in the same footprint size and infrastructure.

Result

The completion of the original and upgraded ZeeWeed MBR plant enabled the city to meet their reuse and capacity needs.

The original plant, and upgraded plant, also meet the California Department of Health Services (DHS) Title 22 requirements for treated reuse water quality parameters. Veolia MBR facilities were the first MBR installations to achieve Title 22 recognition and performance.

The longevity of the original membranes provided costs savings to the city by replacing membranes only once in 13 years, compared to initial expectations of replacing every 7-8 years