Duvall is a small city in the state of Washington with wastewater treatment infrastructure that had reached its capacity.

The wastewater treatment system, originally built to serve a population of approximately 1,000 people, was unable to meet the needs of this fast growing city. Sewer and wastewater treatment limitations led to a building moratorium in 1999, essentially halting the city’s growth, but the population was expected to grow dramatically over the next 20 years and expansion of wastewater treatment capacity was required.

In 2003, the city started construction of what would become Duvall’s largest public works project in its history. The bulk of the original project involved the construction of a state-of-the-art wastewater treatment plant employing membrane bioreactor (MBR) technology; the first of its kind to treat municipal sewage in the state of Washington.

Located on a space-constrained site, the plant at Duvall required compact treatment technology that could retrofit the plant without expanding the footprint. After a full evaluation of several technologies, Veolia was selected to supply a ZeeWeed MBR to upgrade the conventional system.

Since ZeeWeed MBR removes solids by membrane filtration rather than settling, the process is much more effective than conventional treatment, and can operate at much higher mixed liquor suspended solids (MLSS) concentrations to increase system throughput in the same area. The Duvall Wastewater Treatment Plant (WWTP) operates its bioreactor at an MLSS of 12,000 mg/L, compared to 3,000 to 5,000 mg/L for a conventional system, resulting in a significantly smaller plant footprint.

The membranes are installed in outdoor concrete tanks and a new building was constructed to contain the process equipment. Existing tankage was used for part of the biological process. The plant is odor free and architecturally blends into the downtown location.

The original system was designed to treat 1.3 MGD (4,920 m3 /d) of raw sewage and could be easily expanded to treat up to 1.75 MGD (6,625 m3 /d) by installing an additional train of membranes.

At the time, membranes in an MBR system were expected to have a membrane life of 7-8 years. Far exceeding initial expectations, after over 12 years, the plant installed their first set of replacement membranes in 2016. The city determined the best option was to upgrade the MBR portion of their plant with the latest ZeeWeed MBR system using ZeeWeed ZW500D membranes with LEAPmbr* aeration technology.

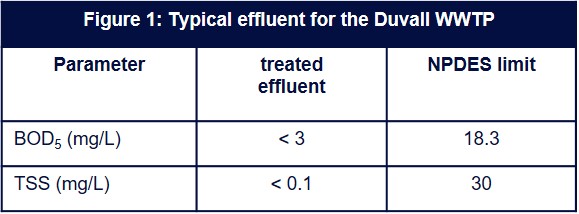

With increased module surface area and improved permeability of the upgraded membranes, Veolia was able to reduce the number of installed cassettes per train to maintain the current 1.3 MGD capacity along with the change to the benefit of LEAPmbr aeration technology, greatly reducing membrane air scour aeration requirements and energy consumption while maintaining excellent effluent quality (Figure 1)

Result

The completion of the original ZeeWeed MBR plant enabled the city to end the building moratorium resulting in economic growth through new, and different businesses, more public spaces, and increased property development. The original plant also created an efficient and effective water quality and recycling program that met the environmental, economic and compact footprint needs of the City of Duvall.

The longevity of the original membranes provided costs savings to the city by replacing membranes only once in 12 years, compared to replacing every 7-8 years.

The upgraded LEAPmbr membranes provided during replacement decreased both the capital and operating costs associated with this membrane upgrade and preserved the footprint needed for the plant and still leaves room for expansion in the future.