Challenge

A common contact cooling system for casting and hot mill operations is uniquely challenged from an organic (oil/glycol) and microbial perspective. Biofilms secreted by sessile (surface) microbes will entrap organics and suspended solids and reduce flow across strainers and spray nozzles. Pluggage of contact cooling water spray nozzles and upstream basket strainers can lead to uneven cooling resulting in off-quality steel production, extended caster downtime, and high maintenance costs.

The ability to effectively treat these systems with high enough levels of oxidizer without impacting water quality due to excessive chlorides is a challenge. In addition, due to the size of these systems and the low cycles of concentration, the ability to utilize non-oxidizing biocides has not proven to be economically feasible. Finally, due to the low tolerance of allowable foam in these systems, the use of biodispersants at effective levels has not proven to be a reliable and effective option.

Solution

This solution required a total team effort between the customer and Veolia. A task force was created to track oil usage, scale pit operation was optimized, new skimmers were added to the scale pit, and communication between all departments of the mill and Veolia was improved.

In addition, a new cooling water treatment program for controlling fouling and enhancing oxidizer performance utilizing Veolia’s new non-foaming Spectrus biodispersant was implemented. This new chemical program, coupled with optimization of bleach feed to the system, provided a cost-effective solution.

Result

Plugged spray water nozzles due to microbiological fouling have essentially been eliminated. The improvement in the cleanliness of the basket strainers ahead of the spray nozzles is shown in the following image.

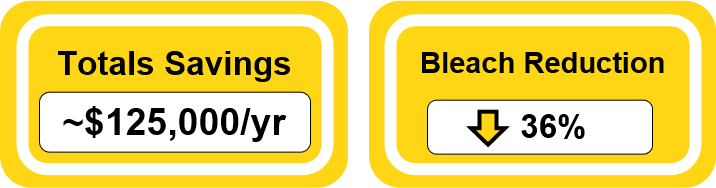

With the improved system cleanliness, the site realized a savings approaching $125K through reduced maintenance and chemical costs. Bleach consumption was lowered by 36%, which allowed the site to reduce chloride impact in the contact spray water system. This is critical not only for achieving desired caster steel quality, but it also allows system cycles of concentration to be optimized, resulting in less water usage and discharge.