memDENSE* Membrane Bioreactor

Unlock MBR potential: Tailor mixed liquor through selective wasting & densification

Unlock MBR potential: Tailor mixed liquor through selective wasting & densification

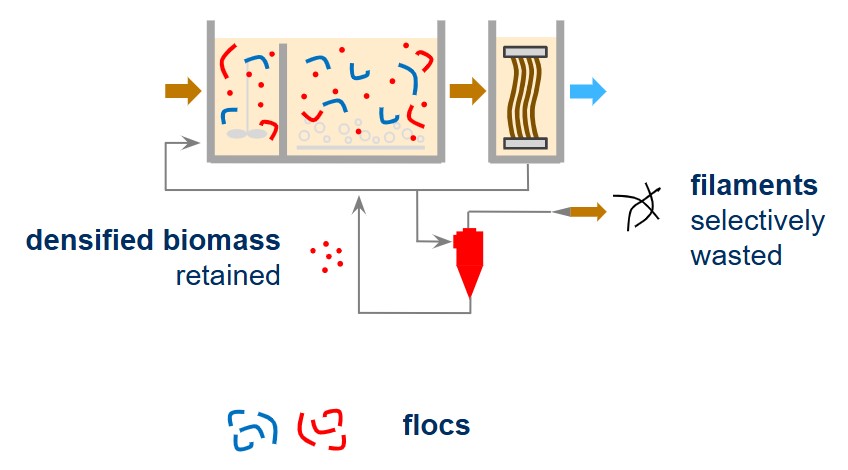

Membrane Bioreactors (MBR) are normally operated with uncontrolled MLSS (Mixed liquor suspended solids) characteristics which limits the full potential of MBR performance. memDENSE MBR combines densification with ZeeWeed* MBR to optimize membrane and biological performance.