ZeeLung* Membrane Aerated Biofilm Reactor

Simple & Sustainable Intensification of Activated Sludge

Simple & Sustainable Intensification of Activated Sludge

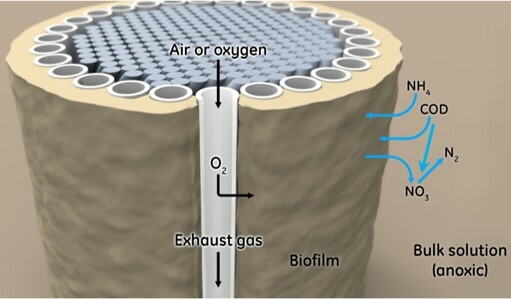

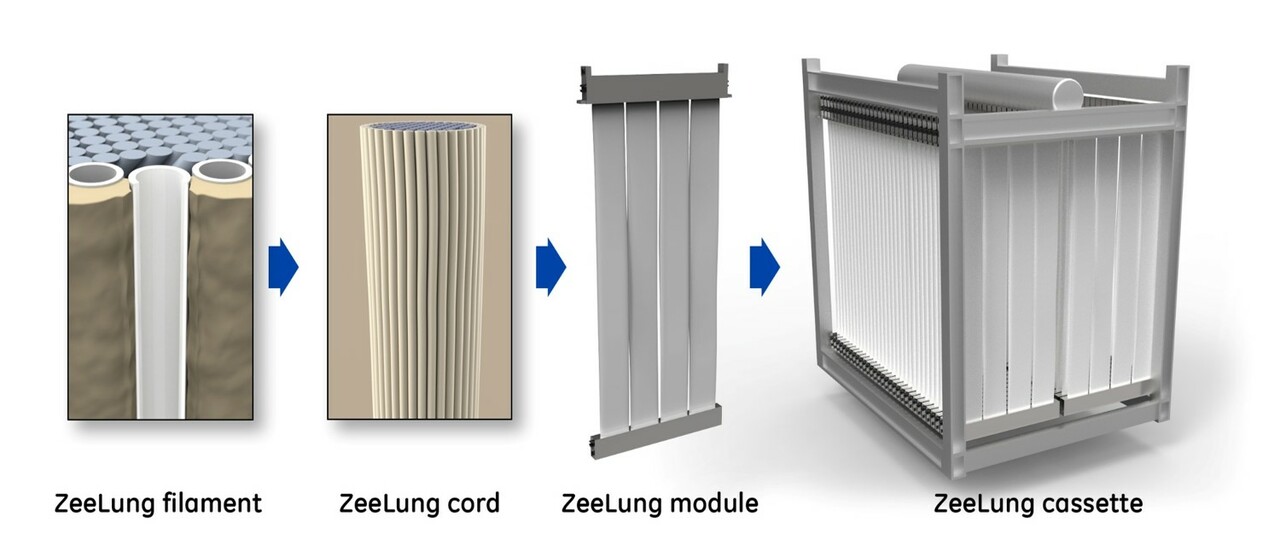

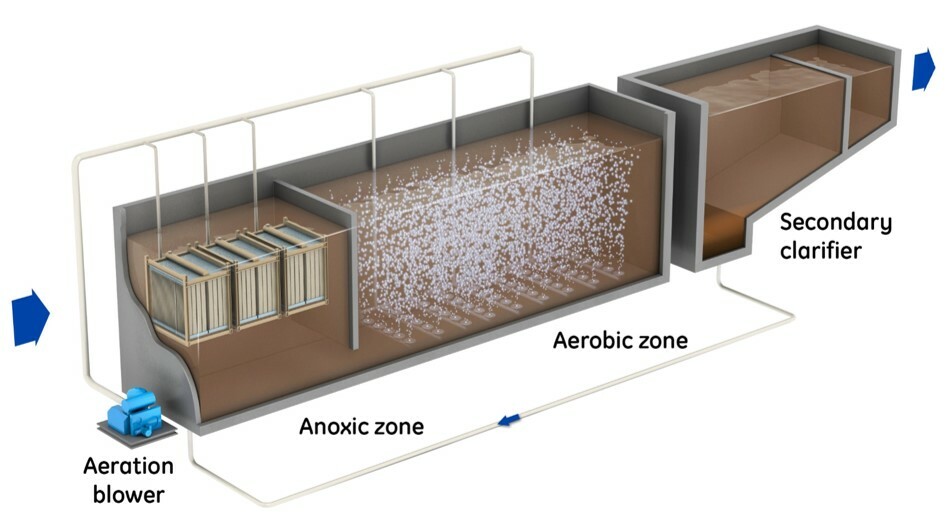

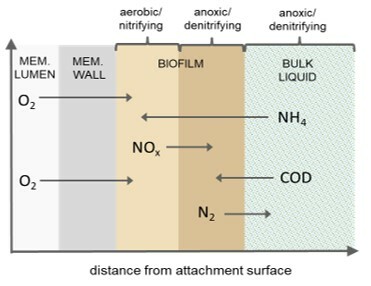

Upgrading wastewater treatment plants for capacity expansion or nutrient removal is challenged by process complexity, the need for larger tank volumes and increased energy consumption.

ZeeLung MABR is an innovative solution that maximizes the treatment capacity from existing tank volumes while also reducing energy consumption. Conventional solutions require the construction of new tanks and other process intensification technologies are complex and energy-inefficient. ZeeLung MABR, on the other hand, is a simple solution that increases treatment capacity in existing assets and reduces energy.

Simple & sustainable wastewater process intensification