High Flow Depth Cartridge Filters

Z.Plex technology optimized for large liquid flows

Z.Plex technology optimized for large liquid flows

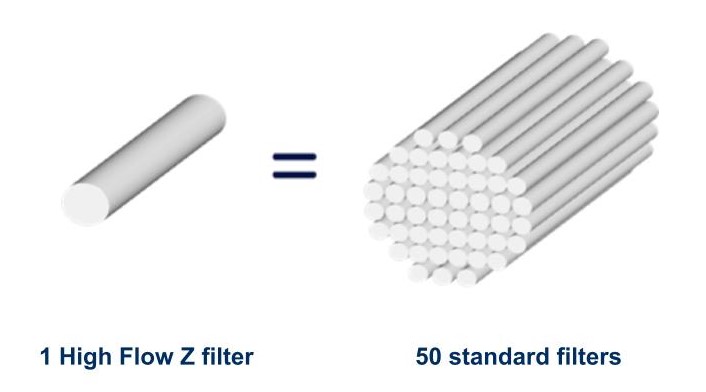

High Flow Z is offered with both absolute and nominal characteristics to fulfill various industrial needs in desalination and oil and gas markets to name a few. High Flow Z is manufactured using patented Z.Plex filter technology and is engineered for high-purity applications. High Flow Z’s proprietary graded density filter matrix provides exceptional performance for high efficiency with high particle-holding capacity and long filter life.