Paraffin/Wax Inhibitors

Paraffin (wax) is a valuable component of hydrocarbon production. It may be present in trace amounts or constitute more than 50% of total hydrocarbon production in some oil fields. It is of critical importance to prevent paraffin from precipitating in the production system, as it is transported from the reservoir to the refinery.

Paraffin naturally crystalizes, precipitates and forms deposits with changes in pressure and temperature. All system locations are at risk of paraffin deposition once the oil cools to its wax appearance temperature (WAT). The WAT could be downhole (i.e., reservoir and near wellbore, perfs, tubing, pumps), or on the surface (i.e., flow lines, valves, headers, separation equipment, tanks, etc.).

When wax deposits form, they attract more wax crystals and grow, eventually blocking the flow channels. In some instances, wax co-precipitates with mineral scale and asphaltene, increasing the complexity of removal and disposal processes.

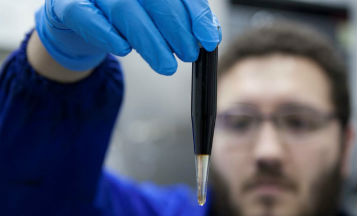

Veolia has formulated specialized ProSolv* Paraffin Control solutions to address paraffin issues consisting of inhibitors, dispersants and solvents. The key is to analyze the fluids and deposits and assess system operating parameters. With this knowledge, an effective paraffin control program can be designed to minimize operating issues and maximize hydrocarbon production and revenue.

ProSolv Paraffin Control Features and Benefits

- Minimizes deposition and production throughput

- Minimizes remediation and intervention to remove paraffin deposits

- Improves safety and reduced the environmental risks due to paraffin

- Fit for use in most oilfield situations

- Can be applied in several ways, including batch and continuous