Membrel* Electrolytic Ozone Generator

State-of-the-art electrolytic ozone generators

State-of-the-art electrolytic ozone generators

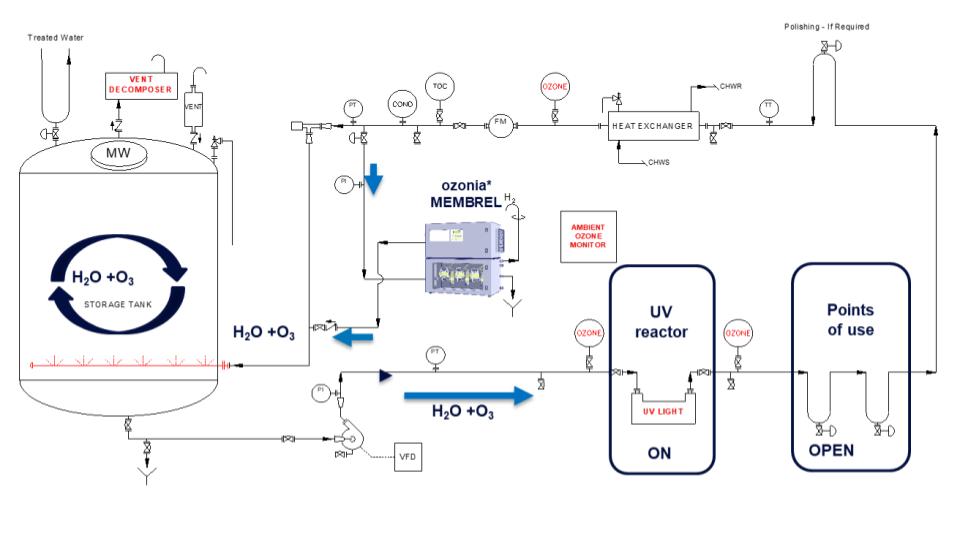

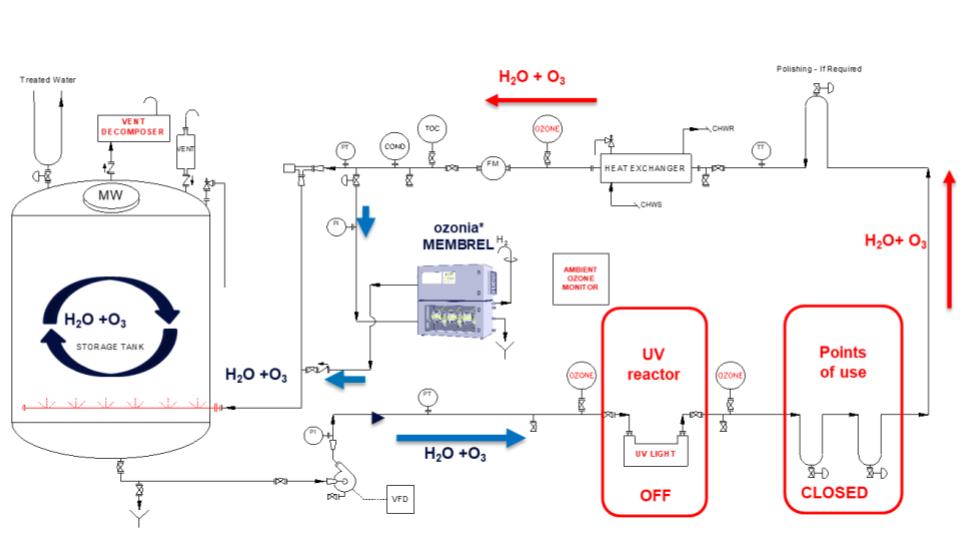

The Membrel Electrolytic Ozone Generators, a brand of Ozonia*, are the most effective way to disinfect ultrapure water systems in industrial and pharmaceutical applications. The Membrel MkV Electrolytic ozone generator produces ozone using a unique method from water instead of gaseous air or oxygen.

The Membrel Electrolytic Ozone Generators continuously secure water and product quality for pure water, ultrapure water (UPW), and process water applications. Electrolytic ozone technology is used in pharmaceuticals, cosmetics, semiconductors, microelectronics, and personal care products markets