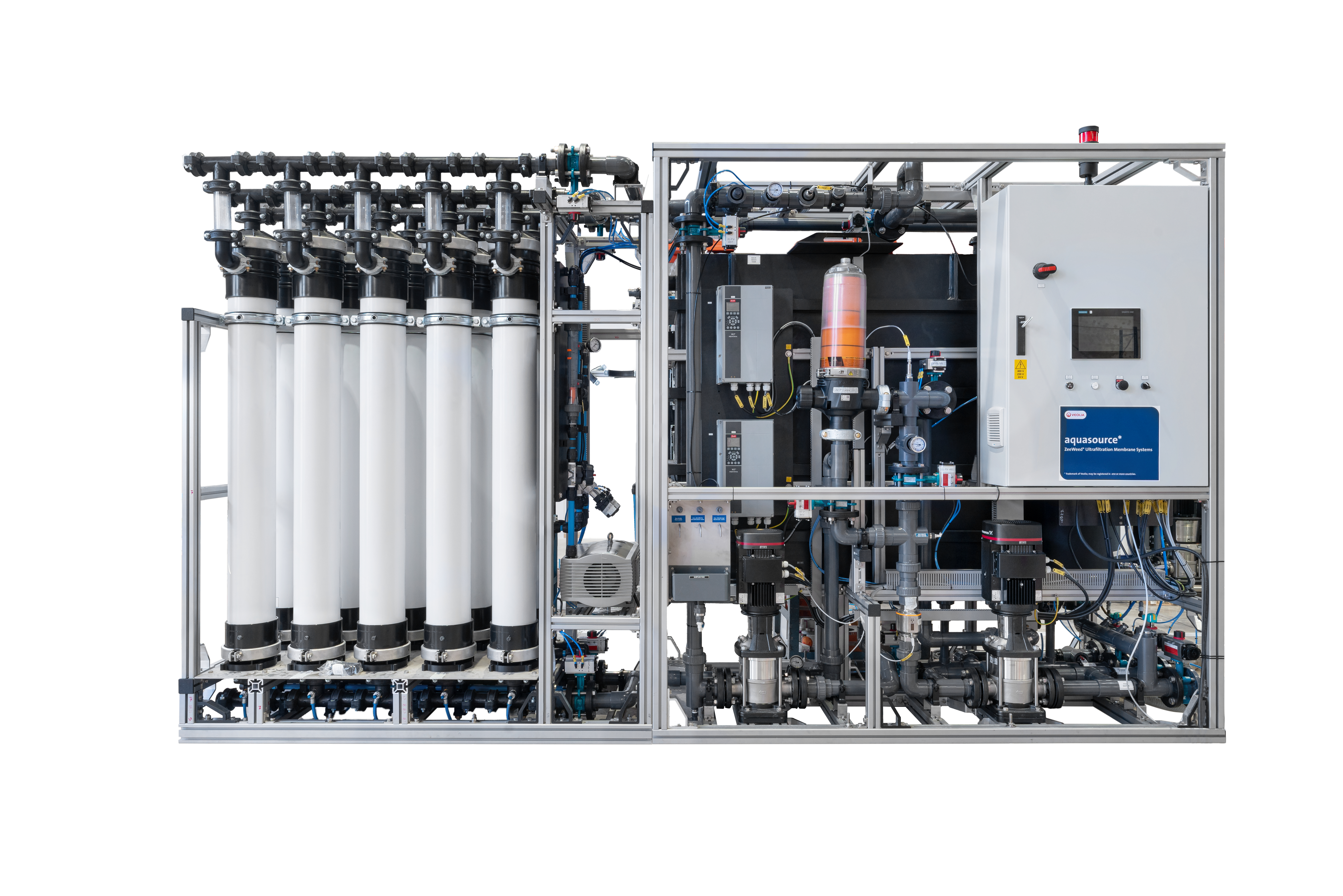

Aquasource* Ultrafiltration (UF) Systems

Smart UF solutions for municipal and industrial clients to produce safe and clean water

Smart UF solutions for municipal and industrial clients to produce safe and clean water

Aquasource products have been the UF industry pioneer for over 30 years and have a large portfolio of installations with proven reliable operation. Aquasource develops smart UF solutions for municipal and industrial clients to produce safe and clean water. Our turnkey systems combine process efficiency and heightened installation flexibility, with solutions producing from 50 to more than 100,000 m3/day and can be used alone or in multi-units installations. These systems have been designed both for new projects and for upgrading existing installations.

- Plug & Play systems

- Low maintenance

- ZeeWeed* membrane technology

- Automatic operational management & remote control