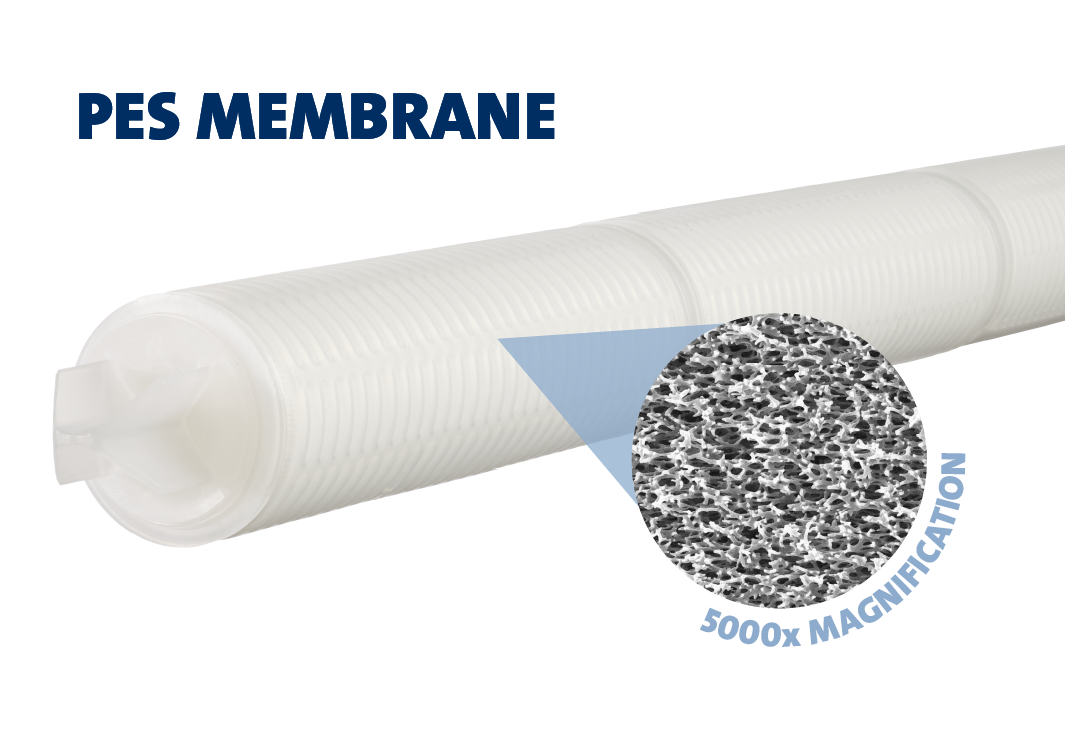

XPleat Pleated Cartridge Filters

XPleat absolute and nominal pleated cartridge filters are designed and manufactured for resistance to a wide range of chemical solutions. Conditions will vary with each application, and users should carefully verify chemical compatibility. XPleat cartridge filters are designed for industrial applications and are tested by lot.