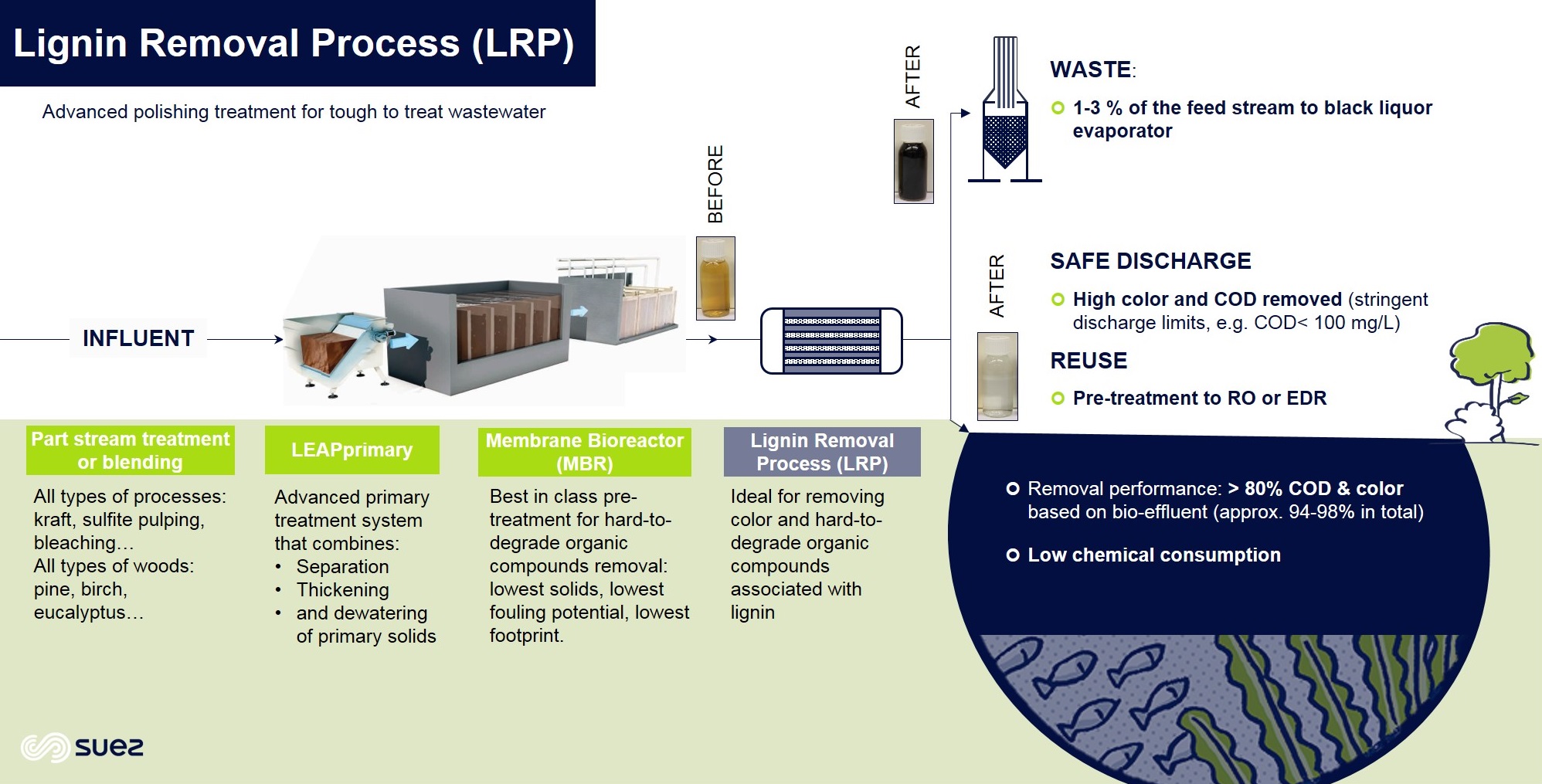

Lignin Removal Process (LPR)

The Pulp & Paper industry witnessed a significant degree of evolution over the last decade, starting with the move from the era of printing to that of packaging and tissue paper production. In a setting of consolidation, segment concentration and increased public awareness, large Pulp & Paper producers are faced with increased pressure to source responsible raw materials, meet stringent environmental regulations such as use less energy and water, create less waste, and ensure clean effluent streams, and need to grow and prosper in a more sustainable and low carbon way.

Lignin Removal Process (LPR)

The Pulp & Paper industry witnessed a significant degree of evolution over the last decade, starting with the move from the era of printing to that of packaging and tissue paper production. In a setting of consolidation, segment concentration and increased public awareness, large Pulp & Paper producers are faced with increased pressure to source responsible raw materials, meet stringent environmental regulations such as use less energy and water, create less waste, and ensure clean effluent streams, and need to grow and prosper in a more sustainable and low carbon way.