A Midwest ethanol production facility had been conducting clean-in-place (CIP) of its evaporators using a basic scheduled cleaning frequency and existing performance data interpretation. The addition of antifoulant chemistry was intended to control fouling in the evaps that relied on feedback from existing measurements, as well as planned scheduling of individual vessel.

The operations department realized that their cleaning process could be improved by conducting CIPs predictively only when needed, only on the vessels that required it. By doing so, it would reduce unnecessary downtime, maintenance costs and chemical usage.

Veolia offered to implement its exclusive IVAP evaporator performance analytics at the plant in order to track individual evap performance and optimize cleaning practices.

IVAP is a unique analytical program developed by Veolia which tracks numerous operating parameters within the evap train. The analytics use data uploaded to Veolia’s cloud-based InSight* APM (Asset Performance Management) system, making operating data and IVAP’s outputs available to operators, as well as technical representatives, for continuous support and troubleshooting.

Result

The real time dashboard incorporated into the plant view screens and weekly reports generated by the IVAP analytics provided the plant with detailed information about the performance of each unit and clear indication of when a CIP was required.

With the help of the IVAP reports, the plant quickly optimized their CIP strategy, only targeting evaporators when they would benefit from a cleaning. The IVAP analytics also helped the plant confirm that a unit was efficiently cleaned, detailing the gain in heat transfer and performance that each cleaning delivered.

IVAP also helped the plant optimize the antifoulant dosage to the evaps by helping them understand what level of treatment had the maximum impact on preventing heat transfer loss over time.

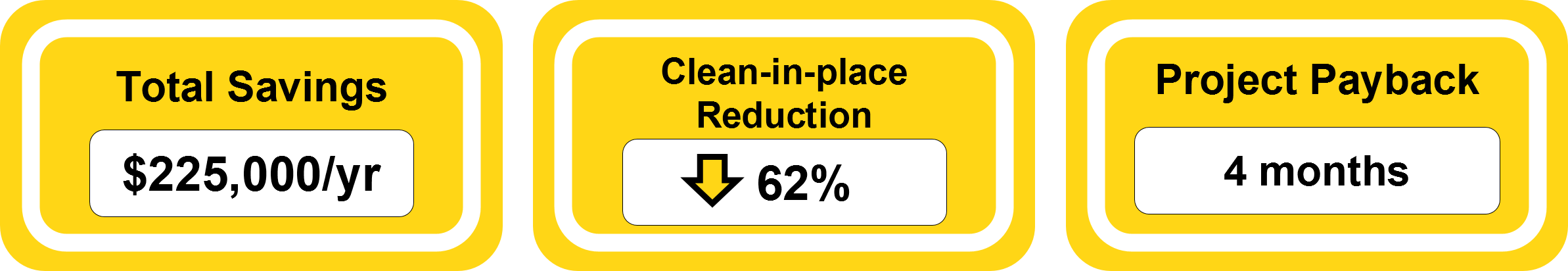

With this data-driven CIP strategy, the plant reduced CIP frequency by 62%, reducing cleaning chemicals by the same proportion. Overall operational savings from a combination of CIP reduction and reduction in antifoulant feed resulted in $225,000 per year in savings. This resulted in a project payback period of only 4 months.

Learn more about our Dry Milling Ethanol Treatment Solutions