FPSO Sulfate Removal Systems

Flexible and modular solutions for sulfate removal

Veolia's pre-engineered solutions for sulfate removal rely on extensive global experience in engineering and manufacturing of water treatment technologies as well as expertise in the Oil & Gas industry.

Sulfate Removal Process Package

Veolia’s Sulfate Removal Process Package consists of a proprietary process design for the entire sulfate removal unit, pre-engineered modules with Veolia's technology, detailed equipment specifications with data sheets and P&IDs. It is flexible and can incorporate a portion of the sulfate removal unit into the customer’s own scope of work, resulting in significant savings to meet local requirements. Combining Veolia’s Process Package offer with our pre-engineered modules enables Veolia to provide a comprehensive process warranty unique to our customers’ needs.

- Process Package Features

-

Veolia works with customers to evaluate pre-selected reputable third-party contractors who will be tasked with detailed engineering, fabrication and integration of the different modules. At each step of the process Veolia approves the engineering, fabrication and integration steps.

Veolia's expertise with chemicals, filters and membranes, pre-engineered solutions provides the customer with direct access to Veolia’s experts for assistance and troubleshooting.

Benefits of Process Packages include:

- Increased execution flexibility to meet local content requirements

- Cost competitive, on-schedule and protected by Veolia's performance guarantees for the entire system vs. individual equipment components

- Direct access to the Veolia technology team for assistance and troubleshooting

- Sulfate Removal Process packages

-

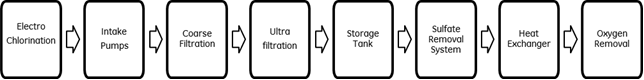

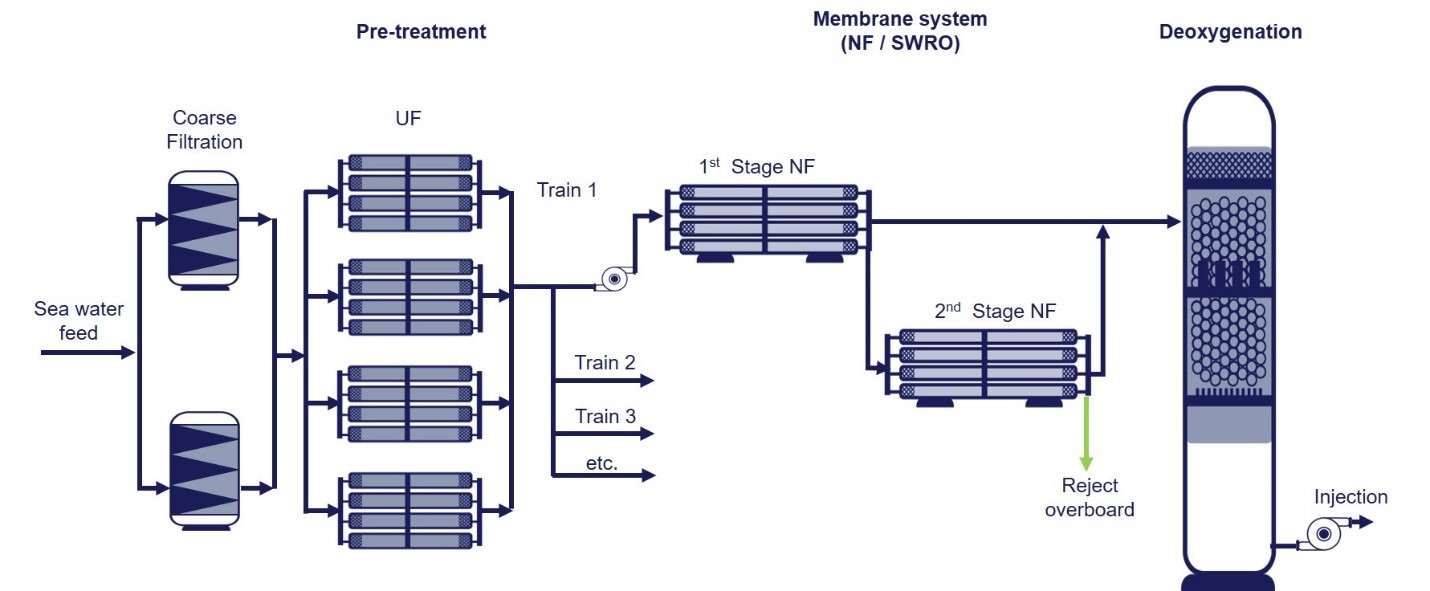

Sulfate Removal is often a vital requirement of offshore water injection systems, with the key requirement being to reduce the natural sulfate content of the seawater down to a level where scaling and souring risks are eliminated.

Veolia is unique amongst topsides water treatment vendors in that we are the only supplier to not only design & build the process plant, but also to manufacture membranes, the key component in both the pre-treatment and sulfate removal processes.

In addition, Veolia is a major manufacturer of the chemicals needed for water treatment production and membrane cleaning.

- The Veolia Advantage

-

Combining a deep understanding of membranes, chemicals and many operating references of offshore water injection plant gives clients ‘the Veolia advantage’ in ownership of a custom-designed solution with extensive built-in knowledge and experience.

Veolia can take full responsibility for the complete sulfate removal module which would be fabricated at a location convenient for the client, benefiting from our existing global relationships with shipyards and manufacturers.

Sulfate Removal Systems

Veolia's pre-engineered solutions for sulfate removal rely on extensive global experience in engineering and manufacturing of water treatment technologies as well as expertise in the Oil & Gas industry. Veolia offers superior standardization and optimization for system design while addressing the challenging environment and strict requirements of the upstream Oil & Gas industry.

Our sulfate removal solutions address and facilitate specific operational and maintenance needs enabling our clients to obtain a robust, state of the art system in the shortest amount of time.

- Veolia’s SWSR Series

-

The SWSR Series is designed to produce consistently low sulfate water for injection, helping to prevent strontium and barium sulfate scale in injection wells and better mitigate well souring by reducing sulfate. It uses nanofiltration technology. Read more here

Veolia’s SWSR nanofiltration (NF) membrane is a membrane developed for seawater sulfate removal. It is built on Veolia’s robust NF flat sheet membrane platform, which has been used for over 30 years in some of the most challenging applications. Click to view a partial FPSO installation list here. - Pre-engineered Solutions Features

-

- Increase the level of standardization from project to project

- Reduced engineering expense by adopting standard modular designs for your sulfate removal unit

- Innovative business model that allows engineering firms to offer their integration expertise for Veolia’s pre-engineered units

- A solution that combines advanced technology and makes it easier to integrate into a larger scope

- A wide array of options ranging from a prefiltration , nanofiltration solutions, chemical cleaning and more

Ultrafiltration Pretreatment

Sulfate removal units require pretreatment of seawater for removal of suspended solids and contaminants prior to entering the NF membrane system. Typical pretreatment technologies have included cartridge filters, multimedia filters, or a combination of both. More recently, ultrafiltration has been gaining momentum with Oil & Gas Operators, given the inherent benefits of a tighter pore structure coupled with an automated cleaning / back pulsing function.

Veolia offers two pressurized ultrafiltration options for SWSR pretreatment:

Topside Water injection Projects:

Topside water injection projects built to exact specifications increase investment costs, cause scheduling delays and impact profitability. Veolia’s pre-engineered solutions provide project flexibility, delivering a system that meets or exceeds water injection requirements.