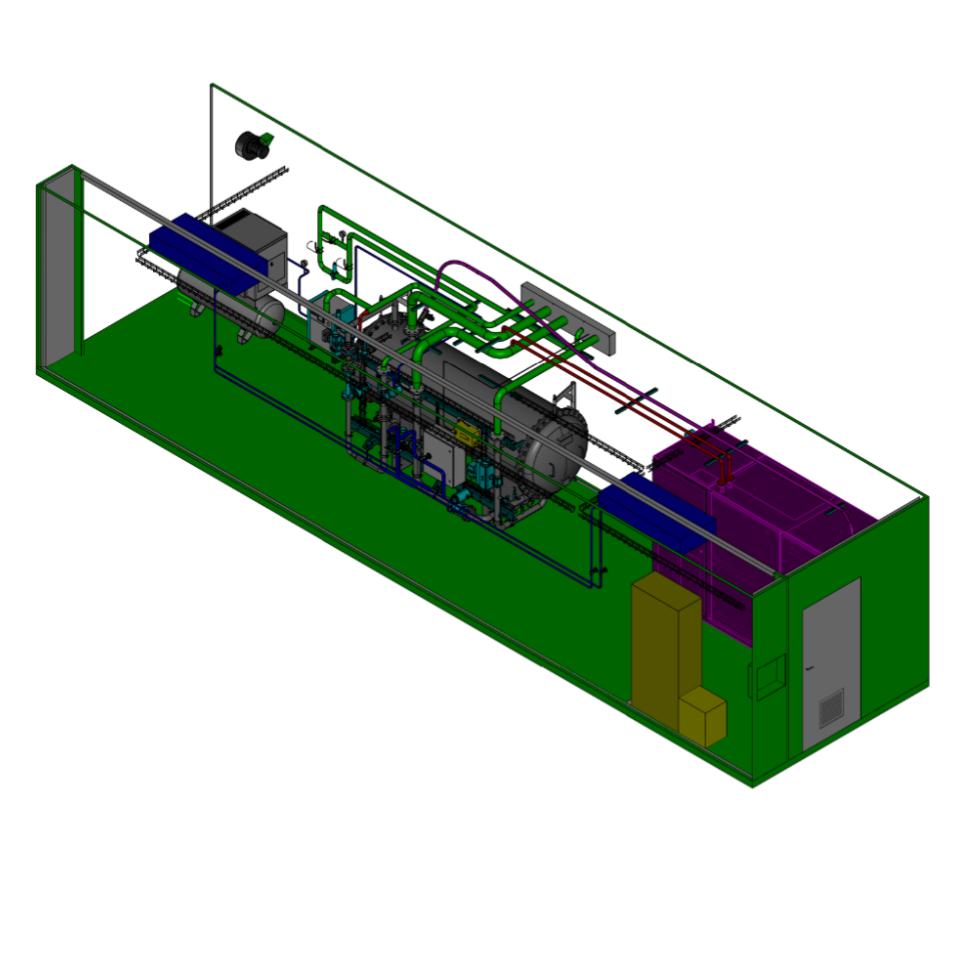

Ozonia Containerized Systems are turn-key ozone systems with all the equipment required for ozone production. Equipment is installed in a container to minimize civil works and start-up time.

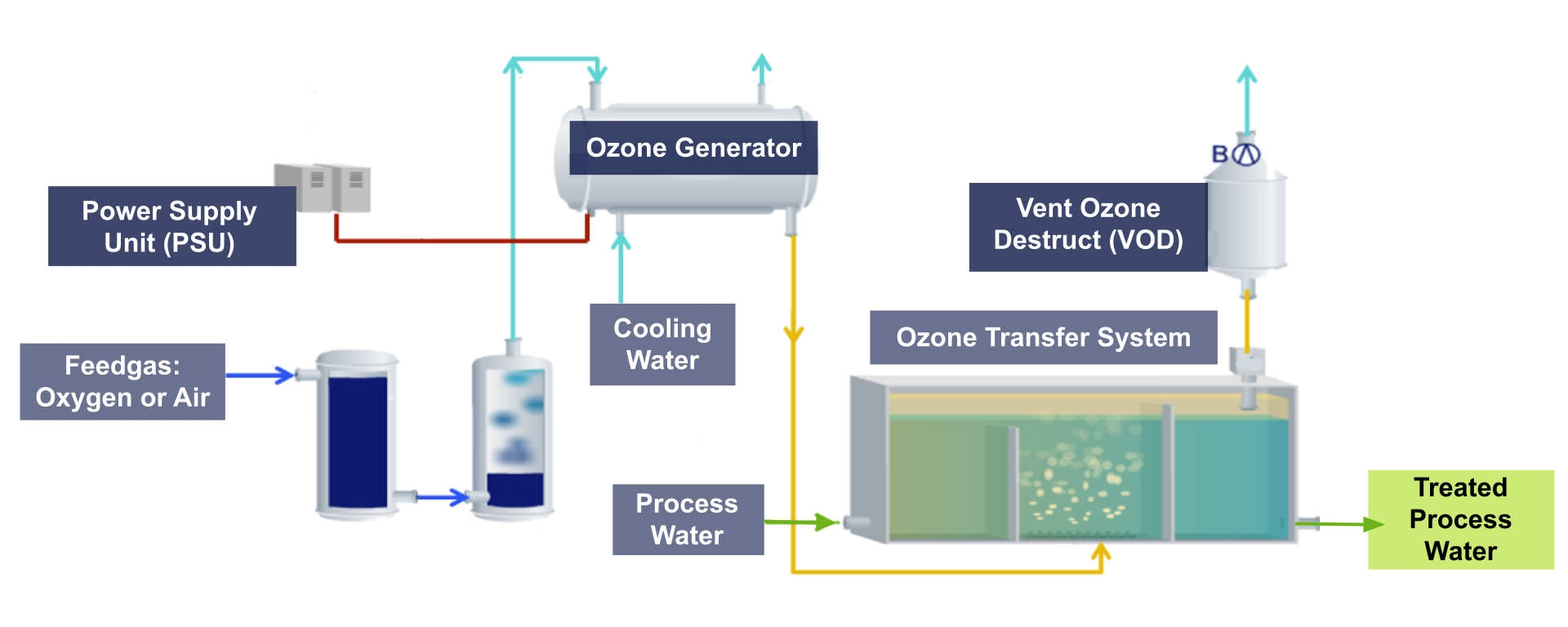

Ozonia Containerized Systems include several main categories of equipment. The most critical parts of the Ozonia Containerized Systems are the ozone generator and container. All the other types of equipment can be incorporated. Ozonia Containerized Systems are very flexible allowing the addition of a wide variety of optional equipment and services to meet each client’s goals.

Components

- Container

- Ozonia Ozone Generator

- Ozone contacting or mass-transfer equipment

- Feed gas preparation equipment

- Cooling water chiller equipment

Containers

Veolia offers a variety of containers to globally recognized standards. We have supplied ISO standard and customized sizes for our clients around the world. ISO 20’ containers provide a compact footprint and easy installation. ISO 40’ containers allow for larger ozone production capacities and contacting equipment. Double-wide containers can also be used to fit to site conditions.

Ozonia Ozone Generators

Ozonia Ozone Generators of all sizes have been used in Ozonia Containerized Systems. The Ozonia Ozone Generator is selected based on the ozone production, ozone concentration and water treatment application.

Ozone contacting mass-transfer equipment

There are 3 types of ozone contacting methods used for ozonation: injectors, porous diffusers or Ozonia radial diffusers. Ozone contacting systems require a volume and time to enable reactions to take place. Contact times between 4 - 20 minutes are normal in ozone applications.

Feedgas equipment

The Ozonia Ozone Generators installed in the containerized plant can be supplied with either dry air or dry oxygen feedgas. The feedgas production method depends on the amount of ozone required and the ozone concentration. Dry air is produced on-site with a suitable compressor and dryer system. For oxygen-based ozone generators, oxygen is drawn from a liquid oxygen (LOX) supply or generated by a Pressure Swing Adsorption (PSA) system.

Cooling water equipment

Cooling water preparation equipment is required when the specified amount or quality of cooling water is not available on-site. The chiller unit can be supplied as a separate unit for installation outside the container where all other components can be installed inside the container.