Coagulants & Flocculants for Water Treatment

Coagulant and flocculant treatment for suspended solids, organics and oil removal, sludge dewatering, and lime softening

Coagulant and flocculant treatment for suspended solids, organics and oil removal, sludge dewatering, and lime softening

During influent water and effluent wastewater treatment, clarification aids like coagulants and flocculants help remove suspended solids, including oil, organics (TOC and color) and hardness. In turn, this allows our customers to prepare their influent raw water for efficient use as process water, meet wastewater discharge regulations reliably, all while allowing for cost-effective water reuse.

Our experts at Veolia provide customers with the peace of mind that can only come from working with professionals who have treated influent and wastewater clarifiers of all types for decades.

Featured Products

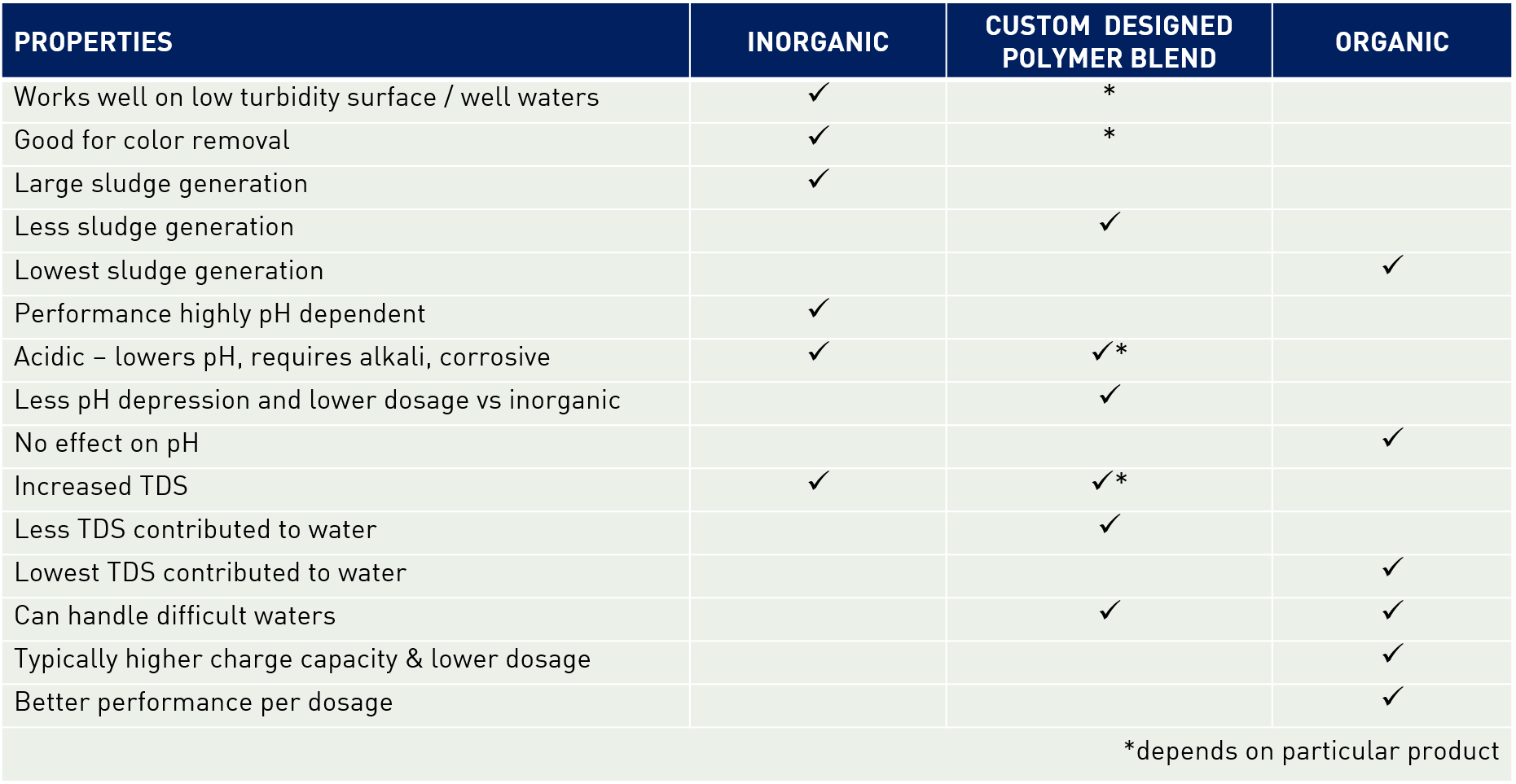

Features & Benefits

Case Studies

KlarAid coagulant improves surface water TOC removal efficiency

A major chemical company required improved TOC removal from surface water clarification treatment to minimize associated downstream fouling.

KlarAid Polymer reduces silt carryover at a chemical plant resulting in reduced process-side chemical treatment

Silt carryover in the influent clarifier at the plant resulted in a need to use further chemical treatment on the process side of the plant.

Influent sludge reduction program saves power plant US$181,100

The unreliability of the lime treatment program in this plant’s influent clarifier resulted in uncontrolled water chemistry with excessive CA hardness/turbidity and high iron levels.

Reducing chemical usage and sludge disposal with new water treatment saves US$55,000

The water treatment plant at a nuclear generating station processing raw water using a competitor’s product asked Veolia to conduct a trial application to see if usage costs could be reduced.

Replacing alum in raw water clarifier improves treatment & reduces sulfur discharge

A chemical plant in the US that produces purified tere-phthalic acid was having difficulty meeting the demand for demineralized water during peak usage following an expansion in production capacity.

Upgrades to refinery wastewater DNF chemistry reduces cost while improving performance

In recent years wastewater has become more challenging to treat for the refiner, and that, with flow variability, contributed to a performance that did not meet the refiner’s high expectations.

Sludge reduction program saves US$350,000 in freight costs

A cellulose acetate plant experiences severe operational problems and freight costs due to the large amount of sludge being generated from its water treatment system.

Better control of chemical feed to dissolved air flotation units saves US$67,500

Because of poor control of a manual feed system for the dissolved air floatation units at this integrated refinery, polymer overfeed occurred frequently.