Introduction

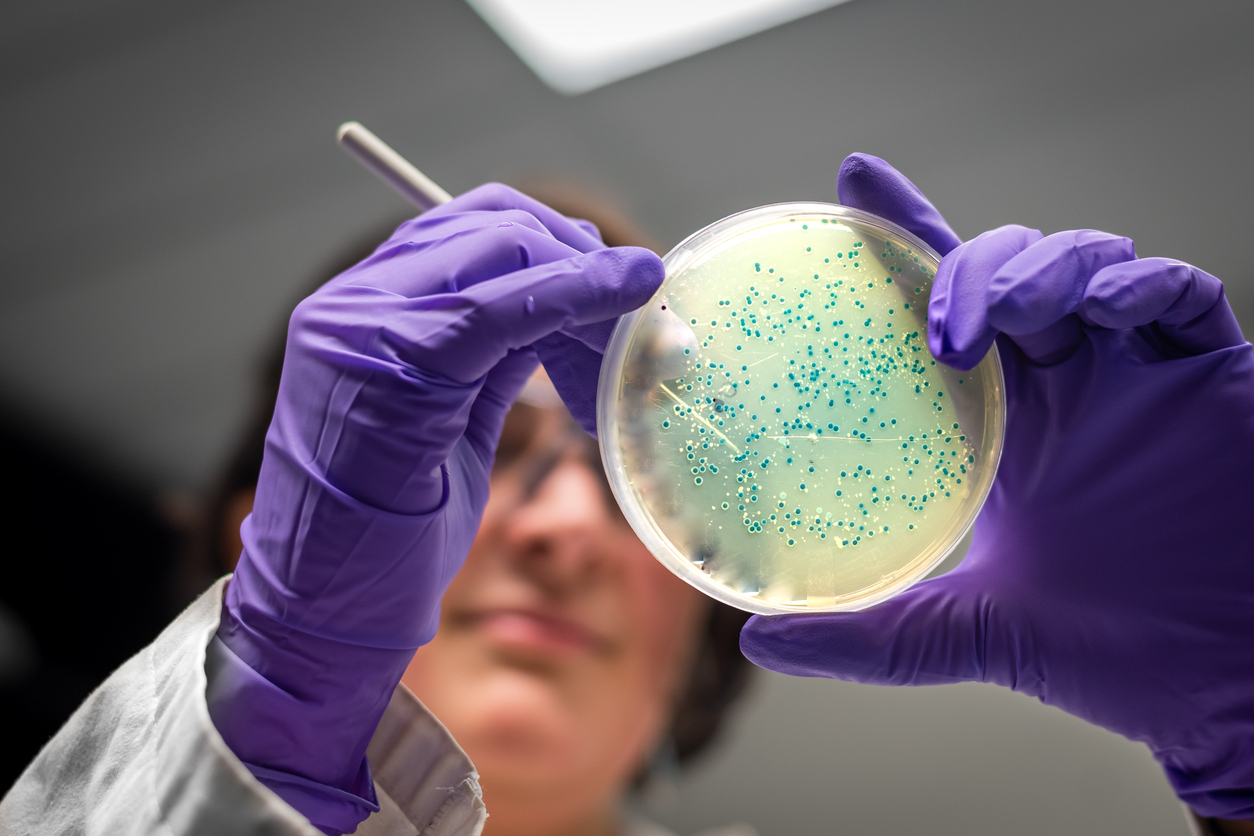

Ensuring the safety and quality of pharmaceutical products is of paramount importance in the healthcare industry. Traditional microbiological testing methods, such as culture-based techniques, have long been the gold standard. However, with the advancement of technology, alternative microbiological methods (such as rapid microbial methods or RMMs) have emerged, offering potential advantages in terms of speed, sensitivity, and automation. The validation of these alternative methods is crucial to guarantee their reliability and accuracy, and to ensure the methods are fit for their intended purpose.

Regulations

The United States Pharmacopeia (USP) <1223> serves as a comprehensive guide for the validation of alternative microbiological methods used in the pharmaceutical industry. This chapter covers a wide range of applications, including microbial enumeration, identification, detection, antimicrobial effectiveness testing, and sterility testing. It encompasses various types of alternative methods, such as RMMs, automated techniques, and molecular approaches like polymerase chain reaction (PCR) and nucleic acid amplification.

According to USP <1223>, the validation process for alternative microbiological methods should address several key aspects. The method's suitability for its intended use must be evaluated, demonstrating equivalent or superior performance compared to the compendial method. This involves assessing factors such as accuracy, precision, specificity, limit of detection, and limit of quantification.

In addition, the alternative method must prove its equivalency to the compendial method by meeting the acceptance criteria outlined in USP <1223>. The method should demonstrate acceptable levels of accuracy, precision, specificity, linearity, robustness, repeatability, and ruggedness. Statistical analysis comparing the alternative method to the compendial method is also a requirement.

In addition to USP <1223>, manufacturers must adhere to guidelines from regulatory bodies such as the FDA, ICH, and EU GMP. Other relevant USP chapters, including USP <51>, <61>, <62>, <63>, <71>, <1058>, and <1225>, should also be considered.

Validation

The validation process should follow a stepwise approach, beginning with identifying user requirements and preparing a User Requirement Specification (URS) document. Instrument qualification, including Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ), is essential to ensure that the equipment meets the manufacturer's specifications and the URS.

Proper documentation is a critical aspect of the validation process. A well-documented validation report should include comprehensive data supporting the method's suitability for its intended purpose. This report must be reviewed and approved by relevant personnel, such as quality assurance or regulatory affairs representatives.

Benefits of Alternative Microbiological Methods

The validation of alternative microbiological methods offers several benefits to pharmaceutical manufacturers. These methods can assist in monitoring the entire production process for microbial contamination more rapidly than traditional compendial methods. Additionally, they can reduce the risk of ergonomic injuries for analysts by minimizing repetitive tasks.

As technology continues to evolve, the adoption of alternative microbiological methods is expected to increase, driven by their potential advantages in speed, automation, and sensitivity. USP <1223> serves as an invaluable resource for manufacturers, providing guidance and ensuring that these alternative methods meet the necessary standards for quality and regulatory compliance.

Instrumentation for rapid microbial methods, accompanied by microorganism verification testing from the instrument vendor in alignment with USP <1223>, allows for confidence and efficiency when implementing an RMM.

Conclusion

In conclusion, the validation of alternative microbiological methods is a critical step in ensuring the safety and quality of pharmaceutical products. By adhering to the guidelines set forth in USP <1223> and complying with regulatory requirements, manufacturers can leverage the advantages of these advanced methods while maintaining the highest standards of quality and patient safety.

Click here to read the full whitepaper

Request more information on the Sievers Soleil Rapid Bioburden Analyzer