If you are monitoring organics in water or evaluating total organic carbon (TOC) instruments, the different monitoring modes are described by multiple acronyms. Perhaps you already have experience with TOC analyzers, so you know what mode you will use or you know what mode you need for compliance reporting (in which case the decision is made quite easily). If you don’t fall into either of these categories though, it might be tricky to understand the differences between modes and which one you should use for your process.

This document describes the differences in simple terms. Below is a list of various modes that can be found in TOC analyzers along with their descriptors and uses. While a TOC analyzer may have multiple modes to support different applications, most instruments will not have every mode.

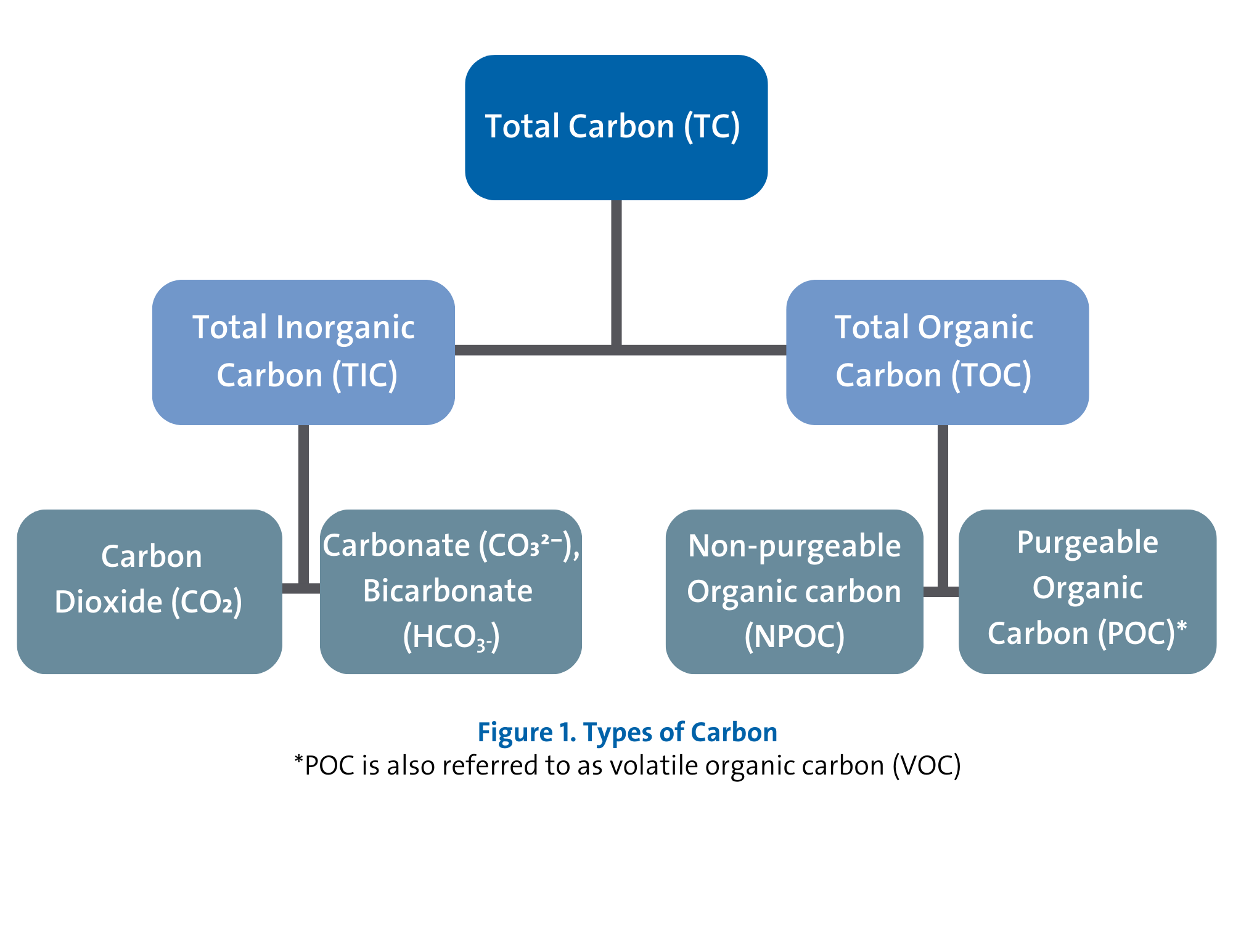

TC: Total Carbon

TC mode measures all carbon species in a sample, both organic and inorganic. This mode does not involve acidifying the sample or purging (more on that in the Inorganic Carbon section below), thus it measures the raw sample as is.

TC mode is best for those who:

Do not need to differentiate between organic and inorganic carbon

Do not want to pretreat samples

Only need trending information

Best applications for TC mode are:

Condensate return

IC: Inorganic Carbon

IC mode targets more specific compounds such as bicarbonate, carbonate and dissolved CO2. Inorganic carbon compounds can be purged by either gassing them off or decreasing the pH to shift the equilibrium to CO2. Without purging and acidifying the sample, the inorganic compounds will remain in solution and will be counted as part of TC. This is a balanced relationship which we will understand more when looking at TOC.

IC mode is best for those who:

Need to detect inorganic compounds for process monitoring to protect equipment and pipes

Need to monitor their water’s buffering capacity

Have samples with consistent pH

Need to prevent boiler scaling (from carbonate deposits)

Need to monitor for membrane degassing

Best applications for IC mode are:

Wastewater treatment plants

Boiler feed water

Drinking water

TOC: Total Organic Carbon

TOC mode is where the inorganic carbon is removed from the total carbon in a sample to determine the total organic content (TC-IC=TOC). Compared to other modes, TOC is more accurate for ppb and sub ppb levels.

TOC mode is best for those who:

Need to monitor and control processes, such as discharge, cleaning or reclaim

Must meet compliance requirements

Need low level sensitivity and accuracy

Have low IC values compared to TOC

Have samples with higher volatile organic compounds (VOC) content

Have samples where the sample matrix can create foam when agitated

Best application for TOC mode are:

Pharmaceutical Ultra Pure Water (UPW) and cleaning validation

Boiler feed water

Semiconductor manufacturing (UPW)

Drinking water

Industrial process water (food and beverage, oil and gas, chemical, etc.)

NPOC: Non-Purgeable Organic Carbon

NPOC mode is the most commonly used and recognizable mode for monitoring organics in industrial process monitoring. In NPOC mode, a sample is acidified to convert the inorganic carbon compounds to CO2. Then the sample is purged with CO2 free air to remove the inorganic or purgeable compounds.The organic carbon (the non-purgeable organic carbon) remaining in the sample is then analyzed. TOC and NPOC are nearly equivalent if purgeable organic carbon (POC) is minimal. NPOC is more accurate for ranges in the ppm levels.

NPOC mode is best for those who:

Need to monitor and control processes

Have samples where the sample matrix has lower POC content

Best applications for NPOC mode are:

Effluent wastewater (industrial or municipal)

POC/VOC: Purgeable Organic Compounds or Volatile Organic Compounds

POC/VOC is a mode used to measure organics that are volatile or semi-volatile. There are two ways to measure VOC: VOC by subtraction and direct measurement using photoionization detection (PID). VOC by subtraction is calculated using the equation VOC = TOC - NPOC. The PID relies on measuring the intermediate positively charged carbon ions that are separated from the sample through purging. These ions are collected on an electrode and the electrical current produced is measured. This mode can be used to obtain TOC values by the sum of NPOC results and POC.

POC/VOC mode is best for those who:

Need to monitor VOCs for control and safety requirements

Do not need to speciate the different VOCs that might be in their sample (bulk value)

Best applications for this POC/VOC mode are:

Petrochemical wastewater

Cooling towers and blowdowns

BOD/COD: Biological Oxygen Demand / Chemical Oxygen Demand

BOD and COD are two fundamental parameters that have been used for determining organic content for decades. BOD determines the amount of oxygen required for degrading microorganisms while COD determines the amount of oxygen required for chemical oxidation of contaminants present. These methods provide an indirect indication of organic contamination by measuring the amount of oxygen consumed - which takes days for BOD and hours for COD. In addition to lengthy analysis times, both methods have compounds that can cause interference. Chlorine and salts cause interference for BOD while sulfides, chlorides, nitrite and ferrous iron can interfere with COD. There are some compounds that are resistant to the chemical oxidation of COD such as benzene. Originally, BOD and COD values were obtained through benchwork in a lab, but because of the previously mentioned drawbacks, there now are several analyzers that offer them by site specific correlation. TOC analyzers directly measure and quantify the carbon present in a sample, and can provide real-time data that is converted into BOD and COD concentrations.

BOD/COD modes are best for those who:

Have regulation requirements to report BOD/COD concentrations

Want to be able to compare the analyzer’s data to lab results

Have samples that do not contain compounds that interfere with BOD/COD measurements

Best applications for BOD/COD modes are:

Effluent wastewater (industrial or municipal)

Conclusion

Choosing which mode to use for your TOC analyzer hinges on more than just what’s on default or most frequently used. The mode that best fits your needs to monitor organics will depend on your sample matrix, application, and what you intend to use the data for. Choosing the right mode from the start will make the implementation process seamless and the data produced thereafter reliable.

Author: Sara Speak

Sara Speak is a Product Application Specialist with Veolia | Water Tech, providing support and application expertise to Sievers Analytical Instruments customers in industries such as chemical, petrochemical, food & beverage, and municipal wastewater.

Sara works with customers to provide training, support product installations, optimize equipment use, and demo feasibility across different testing applications. Prior to her current role, she was a Factory Service Technician, responsible for repairing and troubleshooting Sievers instruments. Sara previously worked in the food and beverage industry as a QA Laboratory Technician at MillerCoors and Leprino Foods. She holds a Bachelor of Science (B.S.) in Chemistry and a Bachelor of Music (B.M.) in Violin Performance from Metropolitan State University of Denver.

- References:

-

- Bonnie Panczak, Hannah Alt, Stefanie Van Wychen, Alicia Sowell, Kaitlin Lesco, and Lieve M.L. Laurens. Determination of Total, Organic, and Inorganic Carbon in Biological Cultures and Liquid Fraction Process Samples. Laboratory Analytical Procedure (LAP), December 31, 2020. National Renewable Energy Laboratory. ://www.nrel.gov/docs/fy21osti/78622.pdf Accessed 07/24/2023.

- Pressac. What are Volatile Compounds and Why Should you be Monitoring them?.11/18/2021.https://www.pressac.com/insights/what-are-volatile-organic-compounds-vocs-and-why-should-you-be-monitoring-them/ Accessed 07/24/2023.

- Ji Won Park, Sang Yeob Kim, Jin Hyung Noh, Young Ho Bae, Jae Woo Lee, Sung Kyu Maeng. A shift from chemical oxygen demand to total organic carbon for stringent industrial wastewater regulations: Utilization of organic matter characteristics. Journal of Environmental Management, Volume 305, 2022, 114412, ISSN 0301-4797.

- https://www.sciencedirect.com/science/article/abs/pii/S0301479721024749 Accessed on 07/24/2023.

- The Wastewater Blog. BOD, COD and TOC. 05/10/2020. https://www.thewastewaterblog.com/single-post/2019/01/13/bod-cod-and-toc Accessed on 07/31/2023.