Water Injection Technology & Process Solutions for EOR

Remove sulfate and enhance oil recovery

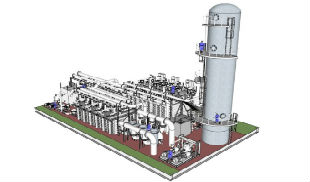

Veolia offers broad solutions for sulfate removal and enhanced oil recovery including pretreatment filters, membranes, chemicals, remote monitoring and diagnostics, pre-engineered solutions, and more. The combination of our expertise in the Oil & Gas industry with our advanced water treatment solutions enables us to provide a comprehensive process warranty that could encompass individual product performance up to an entire water injection system.

From offshore water injection to enhanced oil recovery, Veolia solves your challenges

Offshore water injection consists of injecting seawater into oil reservoirs to maintain or increase oil production. A number of reservoirs, such as those found off the coast of Brazil and West Africa, in the North Sea and in the Gulf of Mexico, require that the water be treated before injection. This treatment consists of removing the sulfate present in seawater to avoid scaling, which would adversely impact oil production. Nanofiltration membranes are typically used for this application, which when in combination with a proper prefiltration scheme and chemical program, ensure that practically all the sulfate is removed from the seawater.

Enhancing oil production can also be achieved through membrane technology by designing water injection systems where water salinity can be adjusted. Recent experiments have shown that reduced salinity water can positively impact the amount of oil being recovered from a series of different reservoirs. This technology can be promising for existing fields in the North Sea and the Gulf of Mexico where oil production is declining. In addition, it may be beneficial to use low salinity technology instead of sulfate removal in early stages since Veolia's salt reducing membranes also remove sulfate from seawater.