The Fundamentals of Total Organic Carbon and Conductivity

What is Total Organic Carbon?

Total Organic Carbon (TOC) is an analytical measurement that indicates the amount of carbon found in organic compounds present in a sample, serving as a key indicator of water quality and purity in pharmaceutical and environmental testing. TOC is critical because even trace organic contamination can compromise product quality and consumer safety. TOC originates from natural sources (i.e. plants and animals) and synthetic materials (i.e. cleaning products, plastics, and pesticides). It's characterized by carbon-hydrogen bonds that can be oxidized to CO2.

A common way to determine the amount of organic carbon in a sample is by subtracting results for Total Carbon (TC) and Inorganic Carbon (IC):

Total Carbon - Inorganic Carbon = Total Organic Carbon, or

TC - IC = TOC, where:

- TC (Total Carbon): All carbon present in a sample, including organic inorganic forms.

- IC (Inorganic Carbon): Carbon present in inorganic compounds (CO2 , HCO3 - and CO32-)

- TOC (Total Organic Carbon): Amount of organic carbon remaining after the inorganic carbon has been removed.

USP <643> establishes standards and procedures for TOC testing in pharmaceutical grade water, specifying technology requirements, system suitability analysis, method validation parameters, and acceptance criteria to ensure water quality and purity.

What is Conductivity?

Conductivity measures a substance's ability to conduct an electrical current, indicating the presence of inorganic chemicals and salts. In pharmaceutical water testing, conductivity serves as a critical quality attribute to detect the presence of ionic species and ensure water purity.

Per USP <645>, conductivity levels must be below 1.3 μS/cm at 25 °C. Conductivity testing detects both intrinsic ions (from dissolved CO2) and extrinsic ions (such as chloride and ammonia), which can harm equipment and human health. Testing is crucial for monitoring salt and inorganic contamination.

Who tests for TOC and Conductivity?

TOC and conductivity testing applications by industry:

- Pharmaceutical: Cleaning validation, Water for Injection (WFI), sterile water, and clean steam.

- Microelectronics: Ultrapure water monitoring and process control

- Municipalities: Drinking water quality, wastewater treatment, and stormwater management

- Food & Beverage: Cleaning processes, wastewater monitoring, release water, and product consistency

- Oil & Gas: Water contamination assessment and process monitoring

How do you measure and test for TOC and Conductivity?

TOC testing involves two critical steps: oxidation and detection. During oxidation, organic compounds in the sample are converted to carbon dioxide (CO2) through established methods including high-temperature catalytic combustion or UV / persulfate oxidation (wet chemical oxidation). Different oxidation techniques are selected depending on application needs, sample matrices, or testing requirements.

The detection phase is where analytical precision becomes crucial, as CO2 measurement accuracy directly determines TOC result reliability. Three primary detection methods include:

- Non-Dispersive Infrared (NDIR) - Measures CO2 through infrared light absorption but suffers from water vapor interference that compromises accuracy

- Direct Conductivity - Measures sample conductivity before and after oxidation but is prone to various interferences

- Membrane Conductometric Detection - Offers robust CO2 measurement while effectively minimizing interferences, providing the most reliable results

When accuracy and precision are non-negotiable, Membrane Conductometric technology enables confident water quality assessment and process control.

For conductivity, common testing methods include two-electrode (contacting) conductivity cells, four-electrode cells, toroidal (inductive) conductivity sensors, and in-line continuous monitoring systems, with measurements typically performed using conductivity meters that apply an A/C voltage across electrodes.

In pharmaceutical water testing, conductivity measurements are governed by USP <645>, which describes three stages of conductivity testing to ensure water meets stringent purity requirements. These measurements are captured temperature-compensated, or non-temperature-compensated conductivity, per the staged requirements in USP <645> to provide a complete assessment of water quality.

TOC and conductivity testing provide complementary measurements of water quality; TOC detects organic contamination while conductivity measures ionic and inorganic impurities, together ensuring comprehensive water purity assessment for pharmaceutical and industrial applications.

TOC and Conductivity with Sievers Analytical Instruments

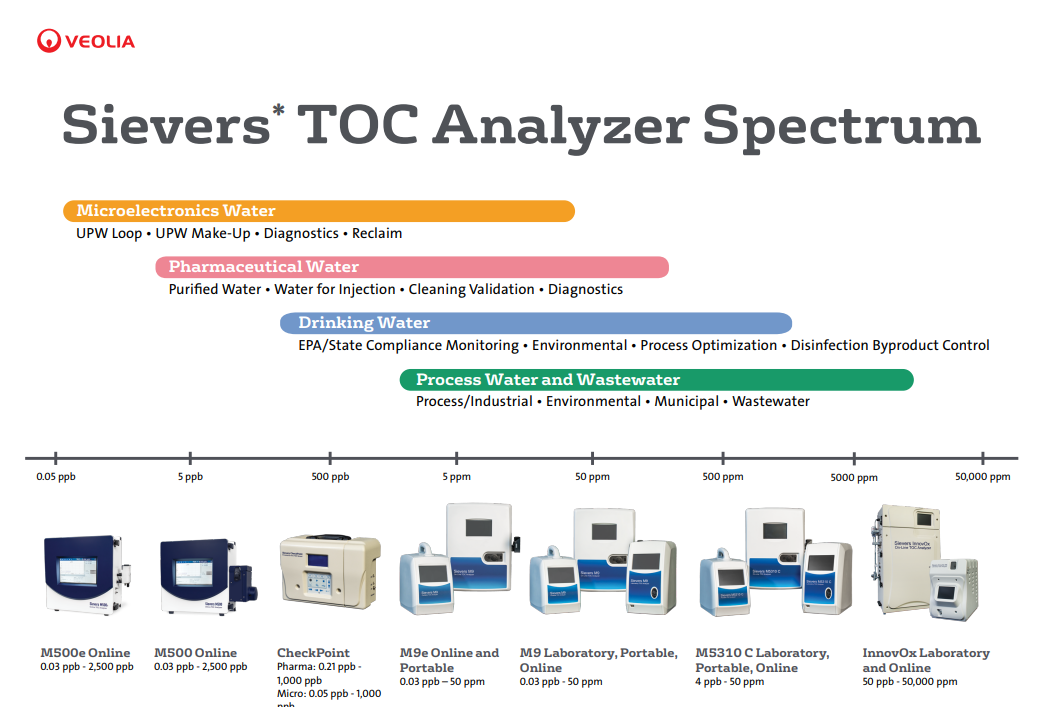

To meet diverse customer needs, Veolia offers a wide variety of analyzers as part of its Sievers portfolio with different analytical ranges and suitability for specific applications, enabling comprehensive solutions across multiple industries. The Sievers Analytical Instruments product line includes advanced solutions for both TOC and conductivity testing.

For TOC and conductivity testing, the Sievers M500, M9, and M5310 C TOC Analyzers deploy membrane conductometric technology to measure both TOC and conductivity. The Sievers technology uses a proprietary gas-permeable membrane to filter CO2 from samples into ultra-pure deionized water. This process allows analysis without interference from other components. The CO2 transfer creates measurable conductivity changes that correlate to IC and TC levels, which allows users to calculate TOC levels.

The Sievers InnovOx TOC Analyzer uses innovative Supercritical Water Oxidation (SCWO), technology that combines heat, pressure, and chemical oxidizers to handle complex samples including oils and fats and other challenging substances.

Direct conductivity, employed by the Sievers CheckPoint TOC Sensor, measures samples before and after UV oxidation.

All of these methods, excluding the Sievers CheckPoint TOC Sensor, follow the fundamental principle of oxidizing organic compounds to CO2, measuring the resultant CO2, and calculating TOC as the difference between total carbon and inorganic carbon. This approach ensures compliance with USP <643> requirements while providing accurate, interference-free detection.

Veolia has established itself as a leader in TOC analysis with its Sievers Analytical Instruments product line. To learn more about implementing TOC and conductivity testing in your operations, watch our on-demand webinar: https://www.watertechnologies.com/lp-ai-online-toc-for-cv-webinar