How to Optimize EDI Power Settings and Performance to Improve Ultrapure Water (UPW) Quality

Introduction: What is Electrodeionization (EDI)

Electrodeionization (EDI) is a critical process in semiconductor ultrapure water (UPW) systems that combines ion exchange (IX) resins, ion-permeable membranes, and high electric potentials to remove ionic contaminants from water. The system operates by using electrical fields to draw ions through exchange resins and across membranes, simultaneously purifying water and regenerating the resins. While this continuous process ensures high-quality ultrapure water through real-time monitoring and voltage control, it requires significant electrical power consumption during operation.

The Importance of Continuous Contamination Control in Microelectronics Manufacturing

Ultrapure water (UPW) quality is a critical component to semiconductor fabrication and the purity of this ingredient is directly tied to wafer yield and product quality. Even trace amounts of contaminants in UPW can cause particle deposits, metal contamination, and surface defects on wafers, leading to reduced device performance and overall quality.

Continuous monitoring and control of UPW systems with tools such as total organic carbon (TOC) monitoring and boron monitoring supports high quality fabrication. With immediate process understanding, manufacturers can respond to deviations quickly and with fewer interruptions to production.

The dynamic nature of UPW systems makes ongoing monitoring particularly important. For example, when EDI system voltages are adjusted, it can take a week or more for contaminant levels to stabilize, during which time the system’s water quality may fluctuate unpredictably. Manufacturers navigate these transition periods with real-time monitoring to make constant adjustments while maintaining wafer production and quality. Without this capability, the alternative is pausing production while contamination clears the system – a costly disruption that can significantly impact manufacturing operational efficiency.

In today's competitive semiconductor landscape, continuous UPW quality control has evolved from beneficial to essential for maintaining both product quality and operational profitability.

Real-time Monitoring of EDI Effluent

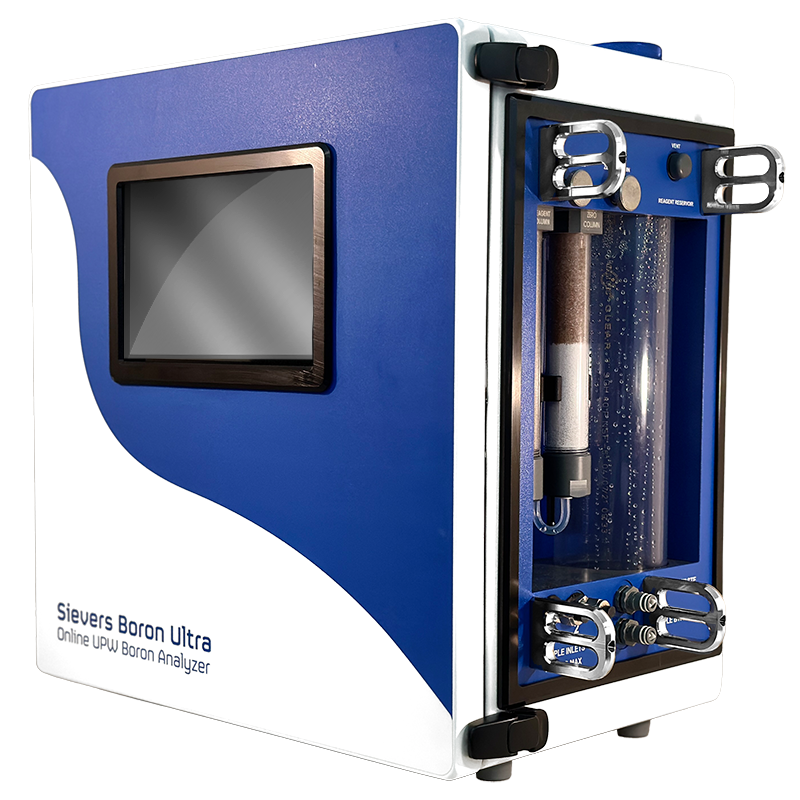

A study with a semiconductor facility tracked critical contaminant levels and overall UPW quality using the Sievers Boron Online UPW Ultra Analyzer and demonstrated the complex relationship between power settings and water quality parameters. While higher power settings were found to more effectively remove contaminants like boron and silica, they also revealed an unexpected drawback: increased EDI voltages promoted the formation of ionic forms of dissolved carbon dioxide, potentially leading to higher conductivity in the UPW. This finding highlighted the delicate balance needed in EDI operations, as excessive power settings could not only increase energy costs but potentially compromise UPW quality.

The research established that EDI effluent quality is determined by three key factors:

- Feedwater quality

- Resin efficiency

- EDI power settings

It yielded data that illustrates the relationship between EDI power and levels of boron, silica, and conductivity in the facility’s effluent, and the monitoring helped engineers implement precise control strategies, remove contaminants, and optimize power consumption, ultimately achieving high water quality standards and operational cost efficiency.

Sievers Boron Ultra Online UPW Analyzer

The Sievers Boron Online UPW Ultra Analyzer serves as a critical tool in modern ultrapure water quality management systems. By delivering continuous monitoring and real-time detection, plants are able to prevent ionic contamination events before they become problematic.

Read the full details of the study here.

Learn more about UPW, the Sievers Boron Online UPW Ultra Analyzer, and the microelectronics industry on our applications page.