- Limiting factors affecting blowdown

- Manual blowdown

- Continuous blowdown

- Energy conservation

- Equipment employed

- Blowdown control

Boiler blowdown is the removal of water from a boiler. Its purpose is to control boiler water parameters within prescribed limits to minimize scale, corrosion, carryover, and other specific problems. Blowdown is also used to remove suspended solids present in the system. These solids are caused by feedwater contamination, by internal chemical treatment precipitates, or by exceeding the solubility limits of otherwise soluble salts.

In effect, some of the boiler water is removed (blowndown) and replaced with feedwater. The percentage of boiler blowdown is as follows:

| quantity blowdown water |

X 100 = % blowdown |

| quantity feedwater |

The blowdown can range from less than 1% when an extremely high-quality feedwater is available to greater than 20% in a critical system with poor-quality feedwater. In plants with sodium zeolite softened makeup water, the percentage is commonly determined by means of a chloride test. In higher-pressure boilers, a soluble, inert material may be added to the boiler water as a tracer to determine the percentage of blowdown. The formula for calculating blowdown percentage using chloride and its derivation are shown in Table 13-1.

Table 13-1. Algebraic proof of blowdown formula.

|

Let x = Quantity feedwater y = quantity blowdown water a = chloride concentration in feedwater b = chloride concentration in boiler water k = percent blowdown By definition of percent blowdown

Because the total chlorides entering the boiler must equal total chlorides leaving boiler,

gives:

|

LIMITING FACTORS AFFECTING BLOWDOWN

The primary purpose of blowdown is to maintain the solids content of boiler water within certain limits. This may be required for specific reasons, such as contamination of the boiler water. In this case, a high blowdown rate is required to eliminate the contaminants as rapidly as possible.

The blowdown rate required for a particular boiler depends on the boiler design, the operating conditions, and the feedwater contaminant levels. In many systems, the blowdown rate is determined according to total dissolved solids. In other systems, alkalinity, silica, or suspended solids levels determine the required blowdown rate.

For many years, boiler blowdown rates were established to limit boiler water contaminants to levels set by the American Boiler Manufacturers' Association (ABMA) in its Standard Guarantee of Steam Purity. These standards were used even though they were of a general nature and not applicable to each individual case. Today, the ASME "Consensus on Operating Practices for the Control of Feedwater and Boiler Water Quality in Modern Industrial Boilers," shown in Table 13-2, is frequently used for establishing blowdown rates.

This consensus applies to deposition control as well as steam quality. Good engineering judgment must be used in all cases. Because each specific boiler system is different, control limits may be different as well. There are many mechanical factors that can affect the blowdown control limits, including boiler design, rating, water level, load characteristics, and type of fuel.

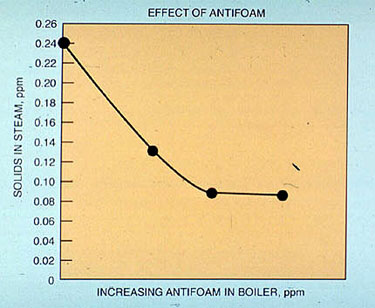

In some cases, the blowdown control limits for a particular system may be determined by operating experience, equipment inspections, or steam purity testing rather than ASME or ABMA water quality criteria. In certain cases, it is possible to exceed standard total solids (or conductivity), silica, or alkalinity limits. Antifoam agents have been applied successfully to allow higher-than-normal solids limits, as shown in Figure 13-1. Chelating and effective dispersant programs also may allow certain water criteria to be exceeded.

The maximum levels possible for each specific system can be determined only from experience. The effect of water characteristics on steam quality can be verified with steam purity testing. However, the effects on internal conditions must be determined from the results observed during the turnaround for the specific unit.

Certain boilers may require lower than normal blowdown levels due to unusual boiler design or operating criteria or an exceptionally pure feedwater requirement. In some plants, boiler blowdown limits are lower than necessary due to a conservative operating philosophy.

Intermittent manual blowdown is designed to remove suspended solids, including any sludge formed in the boiler water. The manual blowdown take-off is usually located in the bottom of the lowest boiler drum, where any sludge formed would tend to settle.

Properly controlled intermittent manual blowdown removes suspended solids, allowing satisfactory boiler operation. Most industrial boiler systems contain both a manual intermittent blowdown and a continuous blowdown system. In practice, the manual blowdown valves are opened periodically in accordance with an operating schedule. To optimize suspended solids removal and operating economy, frequent short blows are preferred to infrequent lengthy blows. Very little sludge is formed in systems using boiler feedwater of exceptionally high quality. The manual blowdown can be less frequent in these systems than in those using feedwater that is contaminated with hardness or iron. The water treatment consultant can recommend an appropriate manual blowdown schedule.

Blowdown valves on the water wall headers of a boiler should be operated in strict accordance with the manufacturer's recommendations. Usually, due to possible circulation problems, water wall headers are not blown down while the unit is steaming. Blowdown normally takes place when the unit is taken out of service or banked. The water level should be watched closely during periods of manual blowdown.

Continuous blowdown, as the term implies, is the continuous removal of water from the boiler. It offers many advantages not provided by the use of bottom blowdown alone. For instance, water may be removed from the location of the highest dissolved solids in the boiler water. As a result, proper boiler water quality can be maintained at all times. Also, a maximum of dissolved solids may be removed with minimal loss of water and heat from the boiler.

Another major benefit of continuous blowdown is the recovery of a large amount of its heat content through the use of blowdown flash tanks and heat exchangers. Control valve settings must be adjusted regularly to increase or decrease the blowdown according to control test results and to maintain close control of boiler water concentrations at all times.

When continuous blowdown is used, manual blowdown is usually limited to approximately one short blow per shift to remove suspended solids which may have settled out near the manual blowdown connection.

Several factors can contribute to reduced energy consumption on the water side of steam generation equipment.

Scale Reduction

Heat transfer is inhibited by scale formation on internal surfaces. Scale reduction through proper pretreatment and internal chemical treatment results in cleaner internal surfaces for more efficient heat transfer and resultant energy savings.

Boiler Water Blowdown Reduction

A reduction in boiler water blowdown can result in significant fuel and water savings.

In some installations, boiler water solids are lower than the maximum level permissible. Through improved control methods, including automatic boiler blowdown equipment, boiler water blowdown can be reduced to maintain the solids close to but not above the maximum level permissible.

The rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. Variations in these factors will change the amount of blowdown required, causing a need for frequent adjustments to the manually operated continuous blowdown system. Even frequent manual adjustment may be inadequate to meet the changes in operating conditions.Table 13-3 illustrates the savings possible with automatic boiler blowdown control.

Blowdown rate is often the most poorly controlled variable of an internal treatment program. Conductivity limits for manually controlled boiler blowdown are usually quite wide, with the lower limits below 70% of the maximum safe value. This is often necessary with manual control because a narrow range cannot be maintained safely.

In plants with sodium zeolite softened makeup water, automatic control systems can maintain boiler water conductivity within 5% of the set-point. Plant operating records have verified that with manual adjustment, continuous blowdown is within this 5% range no more than 20% of the time. In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to automatically controlled continuous blowdown. This reduction is gained without risk of scale or carryover due to high boiler water solids.

In some instances, an increase in feedwater quality permits a significant reduction in the blowdown rate at the existing maximum allowable solids level. This can be accomplished through reuse of additional condensate as feedwater, or through improvement of external treatment methods for higher makeup water quality.

Any reduction in blowdown contributes to water and fuel savings, as illustrated in Table 13-4. When uniform concentrations are maintained at or near maximum permissible levels in the boiler water, savings result in several areas, including makeup water demand, cost of processing water, cost of blowdown water waste treatment, fuel consumption, and chemical treatment requirements. These savings are noticeably greater where makeup water quality is poor, where heat recovery equipment is nonexistent or inefficient, and where operating conditions are frequently changed.

Heat Recovery

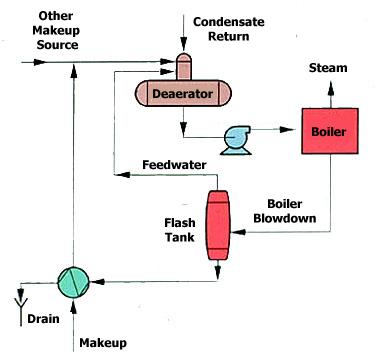

Heat recovery is used frequently to reduce energy losses that result from boiler water blowdown. Figure 13-2 illustrates a typical boiler blowdown heat recovery system using a flash tank and heat exchanger.

Installation of heat recovery equipment is valuable only when energy from the flash tank or the blowdown water can be recovered and utilized. When an excess supply of exhaust or low-pressure steam is already available, there is little justification for installing heat recovery equipment.

If economically justified, boiler water blowdown can be used to heat process streams. In most cases, boiler water blowdown heat recovery systems use flash steam from the flash tank for deaeration. The blowdown from the flash tank is passed through an exchanger and used to preheat boiler makeup water. With the use of an efficient heat exchange unit, the only heat loss is the terminal temperature difference between the incoming makeup water and the blowdown water to the sewer. This difference usually amounts to 10-20°F (5-10°C).

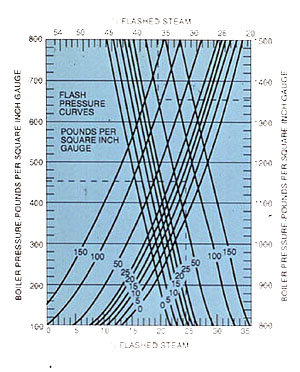

Table 13-5 provides a typical calculation for determining the fuel savings achieved in a heat recovery system using a low-pressure flash tank and heat exchanger. Figure 13-3 can be used to determine the quantity of flash steam recoverable from a flash tank.

Table 13-5. Example of fuel savings possible through use of heat recovery on continuous blowdown.

| Evaporation (steam) | 5,000,000 | lb | |

| Blowdown: | +263,000 | lb/day (5.0%) | |

| Feedwater (steam + blowdown) | 5,263,000 | lb | |

| Boiler Pressure: | 600 | psig | |

| Feedwater Temperature (live steam used): | 240 | °F | |

| Makeup water temperature: | 60 | °F | |

| Fuel (oil) volume | 145,000 | Btu/gal | |

| (@ 75% boiler efficiency) | X 0.75 | ||

| Available fuel heat: | 108,750 | Btu/gal | |

| Employing a flash tank at 5 psig, the quantity of steamavailable may be calculated from the formula: | |||

| % flashed steam = | Hb - Hf |

X 100 |

|

| Vt | |||

| where | |||

| Hb: heat of liquid at boiler pressure | 475 | Btu/lb | |

| Hf: heat of liquid at flash pressure | -196 | Btu/lb | |

|

Vt: latent heat of vaporization at flash pressure |

960

X 100 |

Btu/lb | |

|

% flashed steam = |

29.1 | ||

|

(blowdown) |

263,000 | lb | |

|

(@29.1% flashed steam) |

X.291 | ||

| Flashed steam available at 5 psig: | 76,500 | lb | |

| Total heat of flashed steam at 5 psig: | 1,156 | Btu/lb | |

|

(Heat of makeup water at 60° F) |

-28 | Btu/lb | |

|

Heat available in flashed steam |

1,128 | Btu/lb | |

|

(flashed steam available) |

X 76,500 | lb | |

| Heat savings in flashed steam | 86,292,000 | Btu | |

| Heat of liquid at psig | 196 | Btu/lb | |

| Heat of liquid at 80° F | - 48 | Btu/lb | |

| Heat recovery | 148 | Btu/lb | |

|

(blowdown) |

263,000 | lb | |

|

(blowdown not flashed) |

X 0.709 | ||

|

(heat recovery) |

X 148 | Btu/lb | |

| Heat savings from heat exchanger: | 27,597,000 | Btu | |

|

(heat savings in flashed steam) |

86,292,000 | Btu | |

| Total heat savings: | 113,889,000 | Btu | |

|

(available fuel heat) |

108,750 | Btu/gal | |

| Fuel savings: | 1.047 | gal | |

|

(@ $0.80/gal) |

X .80 | ||

| Daily savings | $837.60 | ||

| X 365 | days/yr | ||

| Annual savings | $305,724 | ||

Manual Blowdown

Equipment for manual blowdown, considered a part of the boiler and installed with the unit, usually consists of a take-off line, a quick-opening valve, and a shut-off valve. The take-off line is always located in the lowest part of the lowest boiler drum, where the greatest concentration of suspended solids should form.

Several types of water-tube boilers have more than one blowdown connection. They permit blowdown from both ends of the mud drum. Blowdown connections are installed on headers for draining and for removal of suspended solids which may accumulate and restrict circulation. The boiler manufacturer usually specifies certain restrictions on the blowdown of water wall headers. These restrictions should be followed closely.

Continuous Blowdown

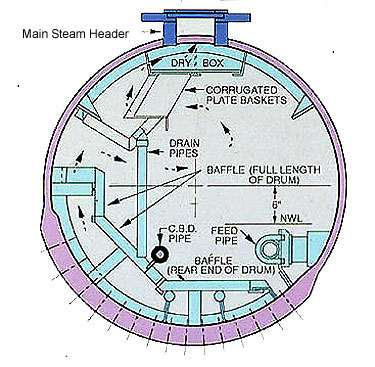

Usually, continuous blowdown equipment is installed by the boiler manufacturer. The exact location of the continuous blowdown take-off line depends primarily on the water circulation pattern. Its position must ensure the removal of the most concentrated water. The line must also be located so that boiler feedwater or chemical feed solution does not flow directly into it. The size of the lines and control valves depends on the quantity of blowdown required.

Figure 13-4 illustrates a typical location in a steam drum for a continuous blowdown connection. In most units, the take-off line is several inches below the low water level. In other designs, the take-off is close to the bottom of the steam drum.

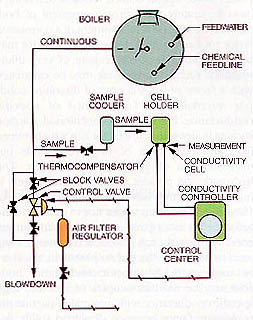

Automatic Blowdown

An automatic blowdown control system continuously monitors the boiler water, adjusts the rate of blowdown, and maintains the specific conductance of the boiler water at the desired level. The basic components of an automatic blowdown control system include a measurement assembly, a control center, and a modulating blowdown control valve. A typical modulating automatic boiler blowdown control system is shown in Figure 13-5.

If an economical blowdown rate is to be maintained, suitable boiler water tests must be run frequently to check concentrations in the boiler water. When sodium zeolite softened makeup is used, the need for boiler blowdown is usually determined by measurement of the boiler water conductivity, which provides an indirect measure of the boiler water dissolved solids.

Other boiler water constituents such as chlorides, sodium, and silica are also used as a means of controlling blowdown. The alkalinity test has been used as a supplementary blowdown control for systems in which boiler water alkalinity can be particularly high.

Total Solids

From a technical standpoint, gravimetric measurement provides a satisfactory way to determine boiler water total solids; however, this method is rarely used because the analysis is time-consuming and is too difficult for routine control. Also, a comparison of the total solids content of boiler water with the total solids content of feedwater does not necessarily provide an accurate measure of the feedwater concentration within the boiler, because of the following:

- the boiler water samples may not show a representative suspended solids content due to settling or deposit formation

- internal treatment can add various solids to the boiler water

- breakdown of bicarbonates and carbonates can liberate carbon dioxide gas and lower the total solids in the boiler water

Dissolved Solids

The specific conductance of boiler water pro-vides an indirect measure of dissolved solids and can usually be used for blowdown control. However, establishing the rate of blowdown on the basis of the relative specific conductance of feedwater and boiler water does not give a direct measure of the feedwater concentrations within the boiler. Specific conductance is affected by the loss of carbon dioxide with steam and by the introduction of solids as internal chemical treatment. Moreover, the specific conductance of feedwater (a dilute solution) and boiler water (a concentrated solution) cannot be compared directly.

The specific conductance of a sample is caused by ionization of the various salts present. In dilute solutions, the dissolved salts are almost completely ionized, so the specific conductance increases proportionally to the dissolved salt concentration. In concentrated solutions, ionization is repressed and the ratio of specific conductance to dissolved salts decreases. The relationship between specific conductance and dissolved solids is determined most accurately through measurement of both parameters and the establishment of a correlation factor for each system. However, the factor may be estimated. The solids content of very dilute solutions such as condensate may be calculated with a factor of 0.5-0.6 ppm of dissolved solids per microsiemens (micromho) of specific conductance. For a more concentrated solution such as boiler water, the factor can vary between 0.55 and 0.90 ppm of dissolved solids per microsiemens of specific conductance. The hydroxide ion present in many boiler waters is highly conductive compared to the other ions. Therefore, it is common practice to neutralize the caustic with an organic acid prior to measuring conductivity. Although gallic acid is conventionally used to neutralize the phenolphthalein alkalinity in samples with high specific conductance, boric acid may be used in samples of low and high specific conductance with minimal impact on the correlation factor between dissolved solids and specific conductance.

Silica, Alkalinity, Sodium, Lithium, and Molybdate

Under certain circumstances, measurement of the silica and alkalinity content of boiler water can be used to control blowdown. Sodium, lithium, and molybdate have been used for accurate calculation of blowdown rates in high-pressure units where demineralized water is used as feedwater.

Chloride

If the chloride concentration in the feedwater is high enough to measure accurately, it can be used to control blowdown and to calculate the rate of blowdown. Because chlorides do not precipitate in the boiler water, the relative chloride concentrations in feedwater and boiler water provide an accurate basis for calculating the rate of blowdown.

The chloride test is unsuitable for this calculation when the feedwater chloride is too low for accurate determination. A slight analytical error in determining feedwater chloride content will cause an appreciable error in calculating blowdown rate.

Specific Gravity

The specific gravity of a boiler water is proportional to the dissolved solids. However, determination of dissolved solids by hydrometer measurement of specific gravity is so inaccurate that it cannot be recommended for proper blowdown control.

Veolia's boiler services include a range of solutions that combine chemistry, equipment, data analysis, and field services to address boiler water performance.

Figure 13-1. Effect of antifoam concentration on steam purity.

Figure 13-2. Typical boiler blowdown heat recovery system using a flash tank and heat exchanger.

Table 13-2. Suggested water quality limitsa.

| Drum Operating Pressureb, MPa (psig) | ||||||||

|

0-2.07 (0-300) |

2.08-3.10 (301-450) |

3.11-4.14 (451-600) |

4.15-5.17 (601-750) |

5.18-6.21 (751-900) |

6.22-6.89 (901-1000) |

6.90-10.34 (1001-1500) |

10.35-10.79 (1501-2000) |

|

| FEEDWATERh | ||||||||

| Dissolved oxygen (mg/L O2) measured before oxygen scavenger additionj | <0.040 | <0.040 | <0.007 | <0.007 | <0.007 | <0.007 | <0.007 | <0.007 |

| Total iron (mg/L Fe) | 0.100 | 0.050 | 0.030 | 0.025 | 0.020 | 0.020 | 0.010 | 0.010 |

| Total Copper (mg/L Cu) | 0.050 | 0.025 | 0.020 | 0.020 | 0.015 | 0.015 | 0.010 | 0.010 |

| Total Hardness (mg/L CaCO3) | 0.300 | 0.300 | 0.200 | 0.200 | 0.100 | 0.100 | --not detectable-- | |

| pH range at 25° C | 7.5-10.0 | 7.5-10.0 | 7.5-10.0 | 7.5-10.0 | 7.5-10.0 | 8.5-9.5 | 9.0-9.6 | 9.0-9.6 |

| Chemicals for preboiler system protection | use only volatile alkaline materials | |||||||

| Nonvolatile TOC (mg/L C)gg |

<1 | <1 | <0.5 | <0.5 | <0.5 | --as low as possible, <0.2-- | ||

| Oily Matter (mg/L) | <1 | <1 | <0.5 | <0.5 | <0.5 | --as low as possible, <0.2-- | ||

| BOILER WATER | ||||||||

| Silica (mg/L SiO2) | £150 | £90 | £40 | £30 | £20 | £8 | £2 | £1 |

| Total alkalinity (mg/L CaCO3) | <350d | <300d | <250d | <200d | <150d | <100d |

--not detectablee-- |

|

| Free Hydroxide alkalinity (mg/L CaCO3)c | --not specified-- |

--not detectablee-- |

||||||

| Specific conductance (µS/cm) (µmho/cm at 25° C without neutralization | <3500f | <3000f | <2500f | <2000f | <1500f | <1000f | £150 | £100 |

a Source: ASME Research Committee on Steam and Water in Thermal Power Systems. Boiler type: industrial water tube, high duty, primary fuel fired, drum type; makeup water percentage: up to 100% of feewater; conditions: includes superheater, turbine drives, or process restriction on steam purity; saturated steam purity target.

b With local heat fluxes >473.2 kW/m2 (>150,000 Btu/hr/ft2), use values for next higher pressure range.

c Minimum level of OH alkalinity in boilers below 6.21MPa (900 psig) must be specified individually with regard to silica solubility and other components of internal treatment.

d Maximum total alkalinity consistent with acceptable steam purity. If necessary override conductance as blowdown control parameter. If makeup is demineralized water at 4.14 MPa (600 psig) to 6.89 MPa (1000 psig), boiler water alkalinity should be that in table for 6.90-10.34 MPa (1001-1500 psig) range.

e Refers to free sodium or potassium hydroxide alkalinity. Some small variable amount of total alkalinity will be present and measurable with the assumed congruent or coordinated phosphate-pH control or volatile treatment employed at these high pressure ranges.

f Maximum values are often not achievable without exceeding suggested maximum alkalinity values, especially in boilers below 6.21 MPa (900 psig) with greater than 20% makeup of water whose total alkalinity is >20% of TDS naturally or after pretreatment by lime-soda or sodium cycle ion exchange softening. Actual permissible conductance values to achieve any desired steam purity must be established for each case by careful steam purity measurement. Relationship between conductance and steam purity is affected by too many variables to allow its reduction to a simple list of tabulated values.

g Nonvolatile TOC is that organic carbon not intentionally added as part of the water treatment regime.

h Boilers below 6.21 MPa (900 psig) with large furnaces, large steam release space, and internal chelant, polymer and/or antifoam treatment can sometimes tolerate higher levels of feedwater impurities than those in the table and still achieve adequate deposition control and steam purity. Removal of these impurities by external pretreatment is always a more positive solution. alternatives must be evaluated as to practicality and economincs in each individual case.

i Values in table assume existence of a deaerator.

j No value given because steam purity achievable depends on many variables, including boiler water total alkalinity and specific conductance as well as design of boiler, steam drum internals, and operating conditions (see footnote f). Because boilers in this category require a relatively high degree of steam purity, other operating parameters must be set as low as necessary to achieve this high purity for protection of the superheaters and turbines and/or to prevent process contamination.

Figure 13-3. Flash steam recoverable from continuous blowdown systems.

|

This chart is used to calculate the percent of boiler water discharged by a continuous blowdown system that can be flashed into steam at a reduced pressure and is recoverable as low pressure steam for heating or process. Example: A boiler operated at a pressure of 450 psig. Continuous blowdown amounts to 10,000 lb/hr. What percentage of blowdown water can be recovered as flashed steam at 10 psig? Solution: Locate 450 psig on the left axis. Follow horizontally toward the right to the intersection with 10 psig "flash" curve (point A). Drop vertically downward to the bottom axis and read 24.5%. (24.5% of 10,000 lb/hr blowdown=2450 lb/hr of flash steam at 10 psig pressure.) These curves have been prepared from the formula:

where Hb = heat of liquid at boiler pressure, Btu/lb Hf = heat of liquid at flash pressure, Btu/lb Vf = latent heat of vaporization at flash pressure, Btu/lb |

|

Note: For boiler pressures between 100 and 800 psig, use "flash" pressure curves slanting from lower left to upper right corner and the bottom axis. For boiler pressures above 800 psig, use "flash" pressure curves slanting from lower right to upper left corner and top axis.

Table 13-3. Example of savings with installation of automatic blowdown equipment (basis: one day).

| Evaporation | 2,400,000 | lb/day |

| Boiler Pressure: | 600 | psig |

| Manual blowdown: | 183,423 | lb/day (7.1%) |

| Automatic blowdown: | 145,069 | lb/day (5.7%) |

| Blowdown Reduction: | 38,354 | lb/day |

| Feedwater temperature: | 240 | °F |

| Makeup water temperature: | 60 | °F |

| Heat of liquid at 600 psig | 475 | Btu/lb |

| Heat of liquid at 60°F | -28 | Btu/lb |

| Heat required: | 447 | Btu/lb |

| (blowdown reduction) | X 38,354 | lb/day |

| Heat reduction: | 17,144,238 | Btu/day |

| Fuel (gas): | 1,040 | Btu/ft3 |

|

(@ 80% boiler efficiency) |

X .80 |

|

| Available fuel heat: | 832 | Btu/ft3 |

| (heat reduction) | 17,144,238 | Btu/day |

|

|

÷ 832 | Btu/ft3 |

| Fuel reduction: | 20,606 | ft3/day |

| Fuel savings @ $4.00/1000 ft3: | $ 82.42 | |

| Labor reduction: | 0.5 | hr |

| Daily labor savings @ $30.00/hr | $ 15.00 | |

| Water reduction: | 4,598 | gal/day |

| Daily water savings @ $ 0.80/1,000 gal: | $ 3.68 | |

| Total daily savings: | $101.10 | |

| X 365 | days/yr | |

| Annual savings | $36,902 |

Figure 13-4. Typical steam drum showing continuous blowdown location.

Table 13-4. Example of fuel savings possible through reduction in blowdown (basis: one day).

| Evaporation (steam) | 2,000,000 | lb/day |

| Present blowdown: | 128,000 | lb/day (6%) |

| Reduced blowdown: | - 41,000 | lb/day (2%) |

| Reduction in blowdown : | 87,000 | lb/day |

| Feedwater (steam plus blowdown): | 2,041,000 | lb |

| Boiler Pressure | 200 | psig |

| Feedwater temperature: | 215 | °F |

| Makeup water temperature: | 60 | °F |

| Fuel (oil): | 145,000 | Btu/gal |

|

(@ 80% boiler efficiency) |

X .80 |

|

| Available fuel heat: | 116,000 | Btu/gal |

| (heat reduction) | 17,144,238 | Btu/day |

| Heat of liquid at boiler pressure: | 362 | Btu/lb |

| Heat of liquid at 60°F: | -28 | Btu/lb |

| Heat required: | 334 | Btu/lb |

| (reduction in blowdown) | 87,000 | lb/day |

| X 334 | Btu/lb | |

| Total Heat Saving: | 29,058,000 | Btu/day |

| +116,000 | ||

| Fuel savings

(@ $ 0.80/gal) |

250

X 0.80 |

|

| Daily savings: | $ 200 | |

| X 365 | days/yr | |

| Annual savings: | $72,000 |

Figure 13-5. Modulating automatic boiler blowdown equipments